Bring next-gen implants to market faster.

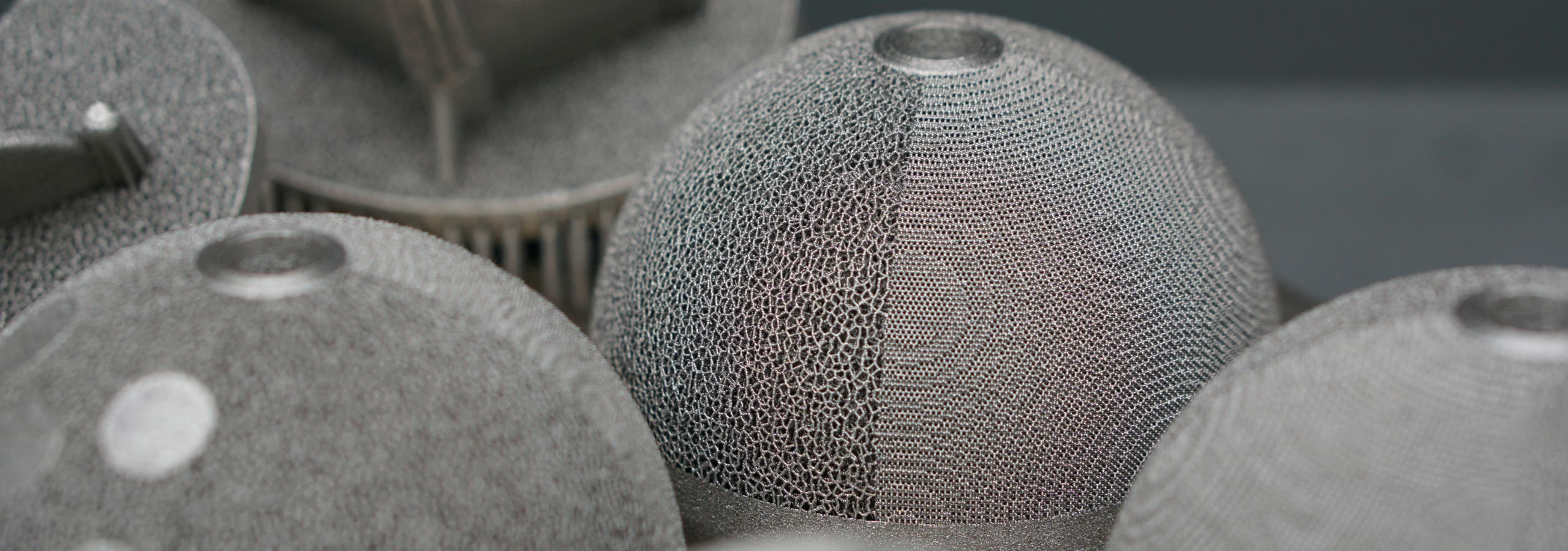

Biofuse™ is a 3D-printed porous ingrowth technology for orthopedic implants.

Produced with advanced L-PBF additive manufacturing, Biofuse™ enables OEMs to create custom lattice structures compliant with ASTM F1854, that integrate seamlessly into their implant geometries.

Leveraging Croom Medical’s proven expertise in lattice engineering, Biofuse™ allows fine-tuning of key parameters such as pore size, porosity, and coefficient friction to create optimal conditions for bone ingrowth and long-term fixation. By combining dense and targeted porous regions in a single manufacturing process, Biofuse™ supports implants that achieve both strong mechanical performance and reliable biological integration.

biofuse lattice Structure

Customise every detail

Coefficient of Friction

- Deliver a high coefficient of friction to promote optimal interconnectivity with surrounding bone. Intended to support initial implant stability.

Interconnected Porosity (50-80%)

Fine tune the volume of open space to balance implant stiffness with fluid permeability. Promoting vascularisation and bone in-growth.

Pore Size (100–600 µm)

Configure pore sizes within the optimal window shown in preclinical studies for tissue in‑growth and nutrient transport, without sacrificing mechanical support.

Seamless Lattice Integration

Printing solid and lattice regions in one continuous run, Biofuse™ aims to produce implants with optimised structural performance. Simplifying your supply chain.

Targeted Lattice Application

Apply porous lattice structures exactly where you need them. Even in tight or complex regions that other methods, such as laser texturing or spray coating, can’t reach.

Biofuse™ gives OEMs the flexibility to design lattice structures to their exact requirements.

This might include replicating a porous structure previously produced through coating methods, or proposing lattice characteristics that improve fixation and manufacturability. The flexibility of the platform gives the OEMs confidence that their design intent can be realised consistently and in line with regulatory expectations.

Biofuse™ IN ACTION

Targeted lattice application for every implant.

Unicondylar Knee

Interbody Fusion Cage

Acetabular Cup

Femoral Component (TKA)

Revision Cone

Interbody Fusion Cage

Engineered for superior ingrowth

Traditional treatments only scratch the surface. Biofuse™ delivers a continuous 3D porous network on your implant, delivering depth-to-edge integration and performance.

Laser Texturing

X 2D surface dimensions

X No pore control

X Minimal porosity

X Line-of-sight coverage

X Surface layer integration

X Limited consistency

X Post-build steps required

Spray Coating

X 2D line-of-sight dimension

X Uncontrolled, variable pore size

X Variable porosity

X Exposed faces coverage

X Limited integration (risk of peeling)

X Variable consistency

X Masking/secondary processing required

Biofuse™ 3D-Printed Lattice

- 3D interconnected dimensions

- Precise pore size control

- Tunable porosity

- Complete coverage

- Full integration

- High consistency

- No post-processing

COLLABORATIONS & PARTNERSHIPS

Our innovation partners

Backed by breakthrough R&D

Biofuse™ is underpinned by years of lattice design experience, advanced R&D, and peer-reviewed publications. OEMs can leverage this proven expertise to accelerate implant development and bring reliable implants to market.

- Naab, B., et al. (2024). “Fatigue prediction through quantification of critical defects and crack growth behaviour in additively manufactured Ti‑6Al‑4V alloy”. Materials Science & Engineering A, 903, L95-L103.

- Matthew Osborne, Naresh Koju, and Gordon Smith, Bryan Naab, Shane Keaveney, and Patrick Byrnes. “The Impact of Tantalum Powder Reuse on Build Properties during Laser Powder Bed Fusion”. Proceedings Additive Manufacturing with powder metallurgy conference, June 15th – 18th 2025 Phoenix USA.

- O’Neill I, Dayanand A, Keaveney S, Kourousis KI. “Tensile anisotropy of powder bed fusion steel 316L: A practical study on the effect of build orientation”. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications. 2024;238(10):2035-2042. doi:10.1177/14644207241238916

- F.R. Kaschel, S. Keaveney, D.P. Dowling, “Comparison between continuous and modulated wave laser emission modes for the selective laser melting of Ti-6Al-4V: Dimensional accuracy, microstructure and mechanical behaviour”, Additive Manufacturing, Volume 55, 2022.

- Muhannad Ahmed Obeidi, Andre Mussatto, Merve Nur Dogu, Sithara P. Sreenilayam, Eanna McCarthy, Inam Ul Ahad, Shane Keaveney, Dermot Brabazon, “Laser surface polishing of Ti-6Al-4V parts manufactured by laser powder bed fusion,” Surface and Coatings Technology, Volume 434, 2022.

- Gorman, M. G., Jones, M., Keaveney, S., Read, J. S., Dias, B., Osborn, K., Shadbolt, J., Jarvis, P., Foster, S., Naab, B., Osborne, M., Burdiak, G. C., Ringrose, T., Skidmore, J. W., Doyle, H. W. “Equation of state measurements of additively manufactured tantalum up to 437 GPa”, Journal of Applied Physics, 2025, Volume 137, 6/6/2025, https://doi.org/10.1063/5.0264514

- Power, John J., Dowling, Denis P., Keaveney, Shane, Hoare, Cathal, “Analysis of unsupervised and semi-supervised machine learning techniques for print defect detection during laser powder bed fusion”, The International Journal of Advanced Manufacturing Technology, 27 May 2025, https://doi.org/10.1007/s00170-025-15777-4

- Colin Butler, Emmanuel Caplanne, Shane Keaveney, Jeff Punch, ”Chemical compatibility of various working fluids with additively manufactured materials for two-phase thermal control systems”, Applied Thermal Engineering, Volume 264, 2025, ISSN 1359-4311, https://doi.org/10.1016/j.applthermaleng.2025.125495

- Neha Agarwal, Katelyn Anne Gallagher, Shane Keaveney, James G. Carton, Dermot Brabazon, Muhannad Ahmed Obeidi. “Influence of processing parameters on the corrosion resistance of additively manufactured nitinol parts for biomedical applications”, Results in Materials, Volume 21, 2024, https://doi.org/10.1016/j.rinma.2024.100536.

- Shane Keaveney, Aleksey Shmeliov, Valeria Nicolosi, Denis P. Dowling, “Investigation of process by-products during the Selective Laser Melting of Ti6AL4V powder”, Additive Manufacturing, Volume 36, 2020.

- McConnell, S., Tanner, D. A., & Kourousis, K. I. (2024). Productivity improvement opportunities for metal powder bed fusion technologies: A systematic literature review. Rapid Prototyping Journal, 30(11). DOI: 10.1108/RPJ-09-2023-0333.

- McConnell, S., Beshay, Y., Kourousis, K. I., & Tanner, D. A. (2025). Increasing productivity for laser powder bed fusion of Ti–6Al–4V parts through increased layer thickness. Progress in Additive Manufacturing. DOI: 10.1007/s40964-025-01079-4.

- WIPO Patent WO2019180208A1 (2019). Biomaterial composition for 3D printing. Inventor: Shane Keaveney et al.

Accelerate your commercialisation plans.

Leverage Biofuse™ to bring differentiated implants to market faster.

Partner with Croom Medical to integrate Biofuse™ porous ingrowth technology into your next device and stand out in a competitive landscape.