Medical Component Manufacturing

Precise parts, large volumes,

24/7 operation

Complex, intricate medical components such as connections, sleeves and adapters produced with extreme accuracy and in large volumes. Our ‘lights-out’ machining centre is equipped with the latest, cutting-edge CNC Milling and Swiss Auto-Turning machines, and, backed by advanced automation, drives super agile, high capacity production.

Lean, cost-effective production

An experienced senior management team focused on delivering lean, clean, streamlined production underpinned by proven processes.

Excellent quality at volume

Our dedicated, senior, and expert quality team collaborates closely with our customers to ensure the delivery of high-precision components at high volumes.

Advanced automation & robots

Our dedicated in-house automation team employ the latest in automation technologies to deliver faster, high-quality and consistent finishing.

The agility to flex to your needs

A vibrant, energetic, agile team, flexible enough to quickly adapt to your needs, and the needs of the market.

The ingenuity to drive lean

We’ve developed a culture open to embracing new technologies, processes and innovations. We challenge the norm, always striving to improve how we work in our quest to drive lean manufacturing.

All in-house

All design, planning, testing, manufacturing, and post-processing work is completed in-house, on-site, allowing for full complete control of quality and timelines.

Capabilities & Machines

Sustained investment in technologies

Our capacity continues to grow as we continually invest in the latest technologies, with over €12M committed in plant, machining and automation advancements since 2019. Helping us to deliver more agility, ingenuity and better processes for our customers.

- DMLS/SLS Additive Manufacturing

- 5-axis CNC Milling & Grinding

- 12-axis CNC Swiss Auto-Turning

- 3-axis CNC Surface Grinding

- Wire & Sinker EDM (Electro Discharge Machining)

- ECM (Electro Chemical Machining)

- CNC Laser Cutting and Welding

- Photochemical Etching

- Welding

- CMM Metrology

- Laser Marking

Our Facility

The scale to consistently deliver

24/7 Production

A growing team of 150+ product builders, engineers and professionals delivering top quality, reliable medical devices.

Certified

Certified to ISO 13485 and 14001 standards. FDA registered facility

Latest, Cutting-Edge Equipment

More than €12M invested in plant & machinery over the past 4 years to advance our capabilities.

On-Site RD&I Lab

We operate our own on-site R&D and materials testing lab for tensile, compression and fatigue testing.

Labour Knowledge & Skills

Situated in Limerick, the centre of Ireland’s MedTech manufacturing cluster with a wealth of labour knowledge and skills in orthopedic manufacturing.

Quality-At-Scale

Producing quality at volume, with 3.5M+ femorals manufactured to date. And we’re growing, with floor space increasing by more than 10,000 sq. feet in 2024.

Sparking innovation

At Croom Medical we foster a culture of curiosity and exploration, continually invest in the latest technologies and closely collaborate with our customers to drive sustained material and process innovation.

- Dedicated, in-house automation team reduce costs & increase quality.

- €12M invested since 2019 to advance our manufacturing capabilities.

- Real-time reporting for transparent customer communications.

- Croom Medical’s industry 4.0 strategy ensures that manufacturing equipment is directly linked to our ERP system where live OEE, PM and SPC analysis can be openly viewed at any time. Customers can receive automated reports twice daily, providing complete transparency on manufacturing progress.

- Using the latest material technologies, including Tantalum.

- In 2022, our RD&I team identified a need for innovative orthopedic joint replacement materials, recognising Tantalum’s superior qualities over Titanium. To harness Tantalum’s potential, Croom Medical has collaborated with Global Advanced Metals (GAM) to establish a cutting-edge additive manufacturing capability using Laser Powder Bed Fusion (3D Printing). Recently, Croom Medical launched its first hybrid Ti-Ta based orthopedic implant prototype.

- Leveraging close partnerships and collaborations.

- For more than a decade, we’ve strategically leveraged industrial and academic partnerships, and actively participated in EU Research Consortiums to drive innovation and business success.

- Award-winning Research, Development & Innovation team

- MedTech Partner/Supplier of the Year 2023, Irish MedTech Awards

- Innovation Excellence Business Award 2023 Finalist, Limerick Chamber

- Best Overall Business of the Year 2021, Limerick Chamber

- Best SME Business: Contribution to the Region 2021, Limerick Chamber

- Contract Manufacturer of the Year 2019, IMR Supplier Award

- Advanced Manufacturing Award 2018, IBEC

- Innovation Award 2017, Enterprise Ireland

- Innovative Project of the Year 2013, Engineers Ireland

- Innovative Project of the Year 2011, Engineers Ireland

- Stryker Supplier of the Year 2007

DEVICES

Extend capacity & advance quality

Tap into our passion for innovation and we’ll help advance quality, extend your capacity and accelerate time to market.

Knee Implants

Femoral implants, patella and tibia implants, and limb salvage.

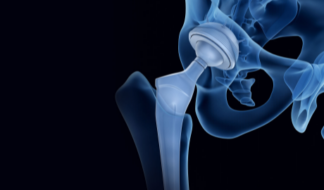

Hip Implants

Hip stems, acetabular cups, femoral heads and femoral liners.

Spine Implants

Interbody cages, pedicle screws and rods, and SI fixation screws.

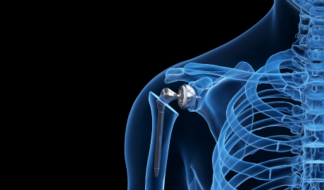

Trauma & Extremities

Shoulder & elbow, foot & ankle, tibia & femur, hand & wrist, cranial & maxofacial.

Capabilities

Joint Partnership

We help drive progress for our medical device customers by enhancing both their production capacity and their product and process innovation.

Manufacturing Capabilities

The facilities, technologies and processes to deliver end-to-end manufacturing.

Value-Add Capabilities

The team, expertise, and ingenuity to drive tangible added-value for our customers.