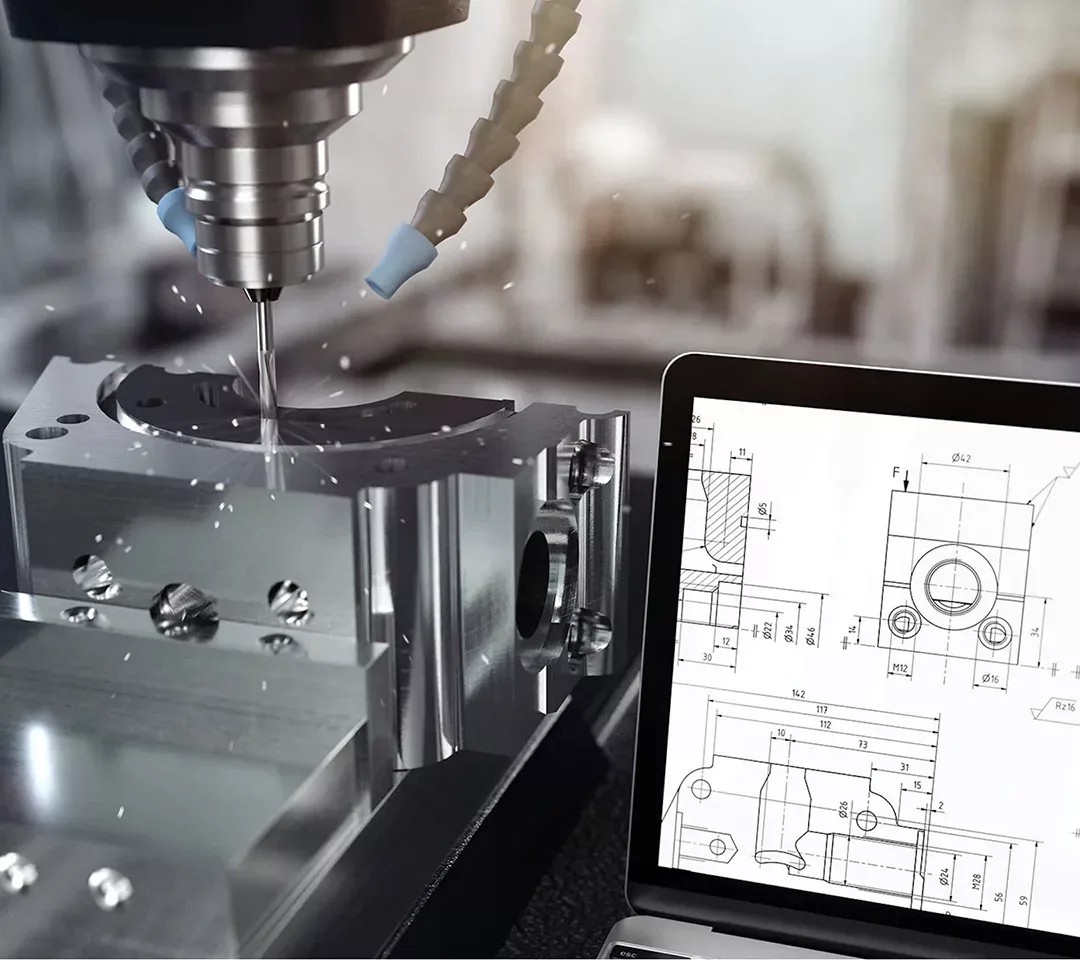

Product & Process Design

Bringing concepts

to reality.

Design for manufacturing.

Our experienced engineers support our OEM customers in their product design and development journey, utilising advanced CAD software to help create bespoke orthopedic implants, with Design for Manufacturing central to our execution.

Design for manufacturing (DFM)

Efficient, cost-effective, quality products

Design for Manufacturing (DFM) is a critical aspect of the product design and development process. Our team of experienced engineers collaborates closely with our customers, ensuring that products are produced efficiently, cost-effectively, and with the highest levels of quality. By considering factors such as material selection, tolerances, and surface finishes at the outset of the design process, we can minimise lead times, reduce waste, and improve the overall quality and reliability of our orthopedic implant solutions.

Design failure mode and effects analysis (DFMEA)

Mitigating risk and improving quality

Our team of experts uses DFMEA as part of our comprehensive approach to quality assurance and risk management throughout the product development lifecycle. DFMEA facilitates the identification of potential failure modes and their effects on the product or system being developed, as well as the causes of those failure modes. This enables us to implement design changes and risk mitigation strategies to ensure the highest level of product performance and reliability.

Process Development

Robust Process Concept Development

Our experienced engineering team use the latest software tools to create detailed process maps and flow diagrams to develop a robust process concept. We also use advanced simulation and modeling tools to optimise the manufacturing process before implementation. This approach enables us to deliver high-quality products with exceptional reliability, performance, and consistency. With a deep understanding of our customers’ needs, we ensure that the process concept meets their requirements for quality, cost, and delivery.

Capabilities

Joint Partnership

We help drive progress for our medical device customers by enhancing both their production capacity and their product and process innovation.

Manufacturing Capabilities

The facilities, technologies and processes to deliver end-to-end manufacturing.

Value-Add Capabilities

The team, expertise, and ingenuity to drive tangible added-value for our customers.