Testing & Inspection

Quality

& reliability.

Dedicated quality team.

We have a team of experienced quality professionals who oversee every aspect of our manufacturing processes, from incoming materials to finished products. Our quality control processes include material analysis, dimensional inspection, surface roughness testing, mechanical property testing, and functional testing.

We also utilise statistical process control (SPC) to ensure consistent quality and identify areas for continuous improvement. Our commitment to quality control has earned us multiple certifications, including ISO 13485, and our customers can trust that every orthopedic implant we produce meets the highest standards of safety and reliability.

Capabilities

- Non-destructive Testing: Fluorescent Penetrant Inspection (FPI) Line

- CMM

- SEM

- X-Ray

- Optical Gauging Products (OGP)

- Visual Inspection

- Hardness Testing

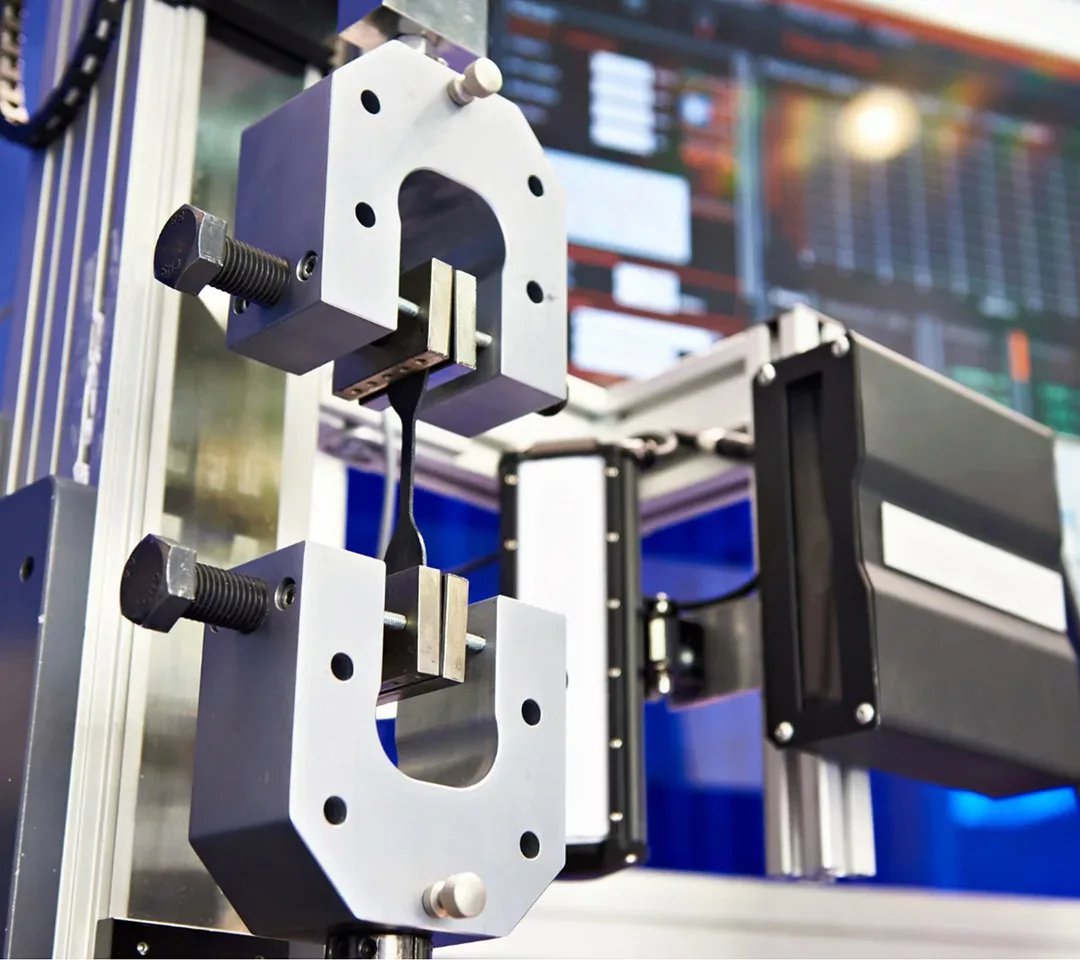

- Mechanical Testing – tensile, compression, and fatigue testing

- Surface Roughness and Finishing Inspection

- Vision Systems

- Software Development Leveraging Artificial Intelligence (AI)

Inspection

Rigorous, detailed, full-cycle inspection

We conduct full-cycle inspection, with checks occurring before, during, and after manufacturing, combining state-of-the-art metrology with stringent machining processes. Once materials are verified, manufacturing processes are controlled by rigorous in-process part inspections. Completed parts are then thoroughly inspected with the latest coordinate measuring machines, technology, and software.

Quality Control

ISO-registered quality program

Quality control is monitored and managed through advanced metrology laboratories with CNC coordinate measuring machines (CMM) and video inspection systems. We inspect gear geometry and evaluate gear accuracy according to our ISO-registered quality program. Dedicated teams ensure all dimensions and metallurgical results are recorded to meet Mil-Spec, ASTM, ANSI, and SAE standards.

Capabilities

Joint Partnership

We help drive progress for our medical device customers by enhancing both their production capacity and their product and process innovation.

Manufacturing Capabilities

The facilities, technologies and processes to deliver end-to-end manufacturing.

Value-Add Capabilities

The team, expertise, and ingenuity to drive tangible added-value for our customers.