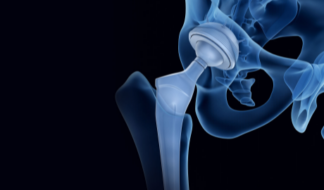

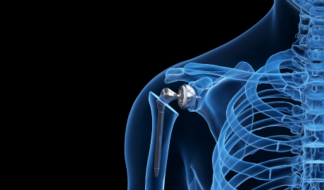

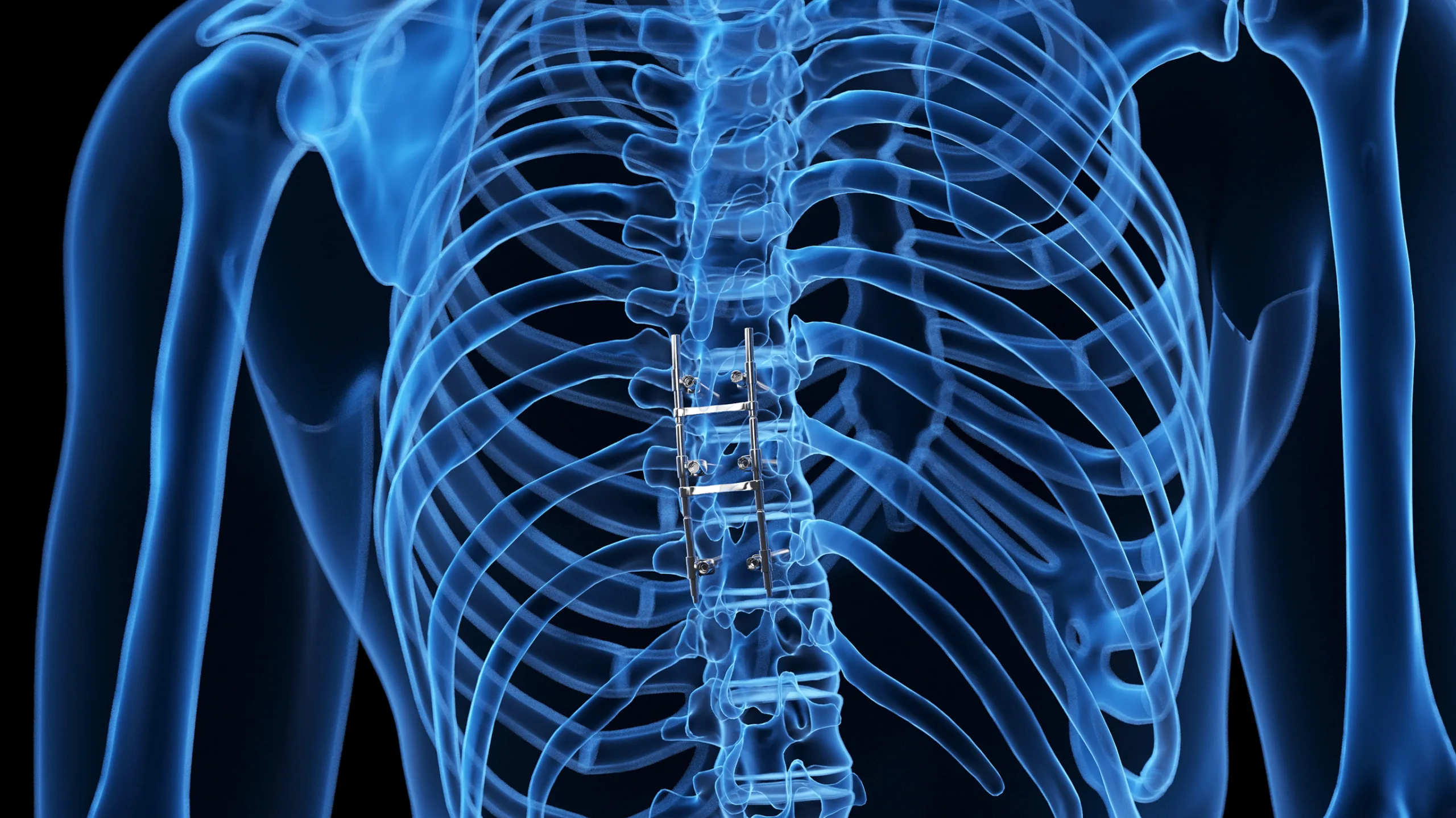

Spine Implants

Tailored, precise

spine implants

Complex geometries and customised shapes.

We offer a range of advanced manufacturing processes for the production of spine implants, including interbody cages, discs, hooks, rings, pedicle screws, plates and rods.

Our state-of-the-art CNC milling and Swiss auto-turning capabilities allow us to create complex geometries and customised shapes, while expertise in metallic additive manufacturing produces porous structures for optimal bone ingrowth. Advanced surface finishing techniques, including automated electropolishing and laser marking, deliver exceptional quality and traceability.

Interbody Cages

Specialised, high-quality cages

We manufacture specialised cages designed for ALIF, PLIF, and TLIF procedures. ALIF cages are large and round to accommodate bone grafts placed through an abdominal incision, while PLIF cages are rectangular for use in back incisions. TLIF cages are rectangular or boomerang-shaped to meet the specific placement angle required for the procedure. All cages are made from high-quality materials and designed to meet the highest standards of safety, reliability, and performance.

Pedicle Screws & Rods

For a wide range of fractures and bone instability

Specialised screws, including cortical, cancellous, and cannulated screws, are manufactured with high-quality materials and are tailored to specific needs.

Dynamic compression plates, low contact dynamic compression plates, buttress plates, and blade plates, are all manufactured to the highest standards of safety and performance, and are designed to support various types of fractures and bone instability.

With all associated fixtures and jigs required for the production scale-up of these implants in-house, our agile team can respond quickly to market demands and tight timelines.

SI Fixation Screws

Advanced osteoconductive structures

Our development of Laser Powder Bed Fusion Systems (3D Printing) includes additive manufacturing of Sacroiliac (SI) Fixation Screws with advanced osteoconductive structures. These cannot be manufactured using conventional machining methods. SI screw fixation is a minimally invasive surgical technique to stabilise the posterior pelvic ring and help combat SI joint dysfunction and trauma.

Manufacturing Capabilities

Leverage our agility, ingenuity, automation and low-cost base to drive down your cost of manufacture. We foster a culture of curiosity and exploration, continually invest in the latest technologies and closely collaborate with our customers to drive sustained material and process innovation. Our capabilities and machinery include the following:

Manufacturing Technologies

- DMLS/SLS Additive Manufacturing

- 5-axis CNC Milling & Grinding

- 12-axis CNC Swiss Auto-Turning

- 3-axis CNC Surface Grinding

- Wire & Sinker EDM (Electro Discharge Machining)

- ECM (Electro Chemical Machining)

- CNC Laser Cutting and Welding

- Photochemical Etching

- Welding

Cleaning & Finishing

- Skilled Hand Polishing

- Mass Media Finishing / Drag Finishing (Ceramic, Plastic and Nutshell)

- Robotic Polishing

- Media Blasting

- Stoning

- Automated Electro Polishing

- Shot Peening & Bead Blasting

- Deburring

- Heat Treatment

- CNC Laser Marking

- Surface Texturing and Patterning

- Automated ultrasonic cleaning

Quality Control

- Non-destructive Testing: Fluorescent Penetrant Inspection (FPI) Line

- CMM

- SEM

- X-Ray

- Optical Gauging Products (OGP)

- Visual Inspection

- Hardness Testing

- Mechanical Testing – tensile, compression, and fatigue testing

- Surface Roughness and Finishing Inspection

- Vision Systems

- Software Development Leveraging Artificial Intelligence (AI)

Committed To Excellence

Croom Medical is committed to maintaining an effective quality management system to ensure compliance with all applicable quality and regulatory requirements, through continual improvement. We share a commitment to long lasting relationships based on trust, by partnering with our customers.

Fully Certified

DEVICES

Extend capacity & advance quality

Tap into our passion for innovation and we’ll help advance quality, extend your capacity and accelerate time to market.