Orthopaedic fixation devices must deliver absolute reliability inside the human body. Among these, titanium bone plates play a crucial role in stabilising fractures and enabling natural bone healing. At Croom Medical, we combine decades of precision engineering expertise with advanced surface treatments to produce titanium bone plates that meet the most demanding medical standards. In this article, we walk through the complete titanium bone plate manufacturing and anodising process, showing how each stage contributes to mechanical strength, biocompatibility, and surgical usability.

Why Titanium?

Titanium, specifically Ti-6Al-4V ELI (Extra Low Interstitial) per ASTM F136, is widely used in orthopaedic implants because of its superior mechanical and biological properties. Its high strength-to-weight ratio and natural corrosion resistance make it ideal for long-term implantation. Furthermore, titanium’s ability to integrate with bone tissue supports healing and stability without compromising biocompatibility.

Key Advantages:

Excellent biocompatibility

Corrosion resistance in physiological environments

High fatigue strength for dynamic loading

Radiolucency that assists post-operative imaging

Compatibility with anodising for improved surface characteristics

Titanium Bone Plate Manufacturing: Step-by-Step Process

Our titanium bone plate process flow follows strict quality control measures from raw material verification to final packaging. Each step is engineered for precision and repeatability.

1. Raw Material Receipt & Verification

The process begins with the receipt of certified titanium alloy bar or plate stock. Each batch is verified against ASTM F136 specifications, ensuring compliance with chemical composition, mechanical properties, and traceability documentation. Material certification and heat lot records are maintained throughout production for full traceability.

2. Cut-to-Length / Stock Preparation

Bars are cut to precise lengths suitable for the required bone plate size. This step minimises waste and prepares the workpiece for efficient CNC machining. Proper fixturing and clean handling at this stage prevent contamination and surface imperfections.

3. CNC Machining

CNC machining defines the plate geometry, contour, and hole pattern with micrometre-level accuracy. Automated, multi-axis machines enable consistent machining of anatomical shapes that mirror the curvature of bones. Tooling strategies and coolant management are carefully controlled to maintain tight tolerances and surface integrity.

4. Thread Milling

Where bone screws interface with the plate, thread milling produces clean, precise threads. Using carbide tooling and optimised cutting parameters prevents galling and ensures perfect screw fitment, critical for surgical performance.

5. Edge Preparation & Deburring

All machined edges are refined to remove burrs or sharp transitions. This enhances handling safety, prevents soft tissue irritation, and promotes uniform surface finishing later in the process.

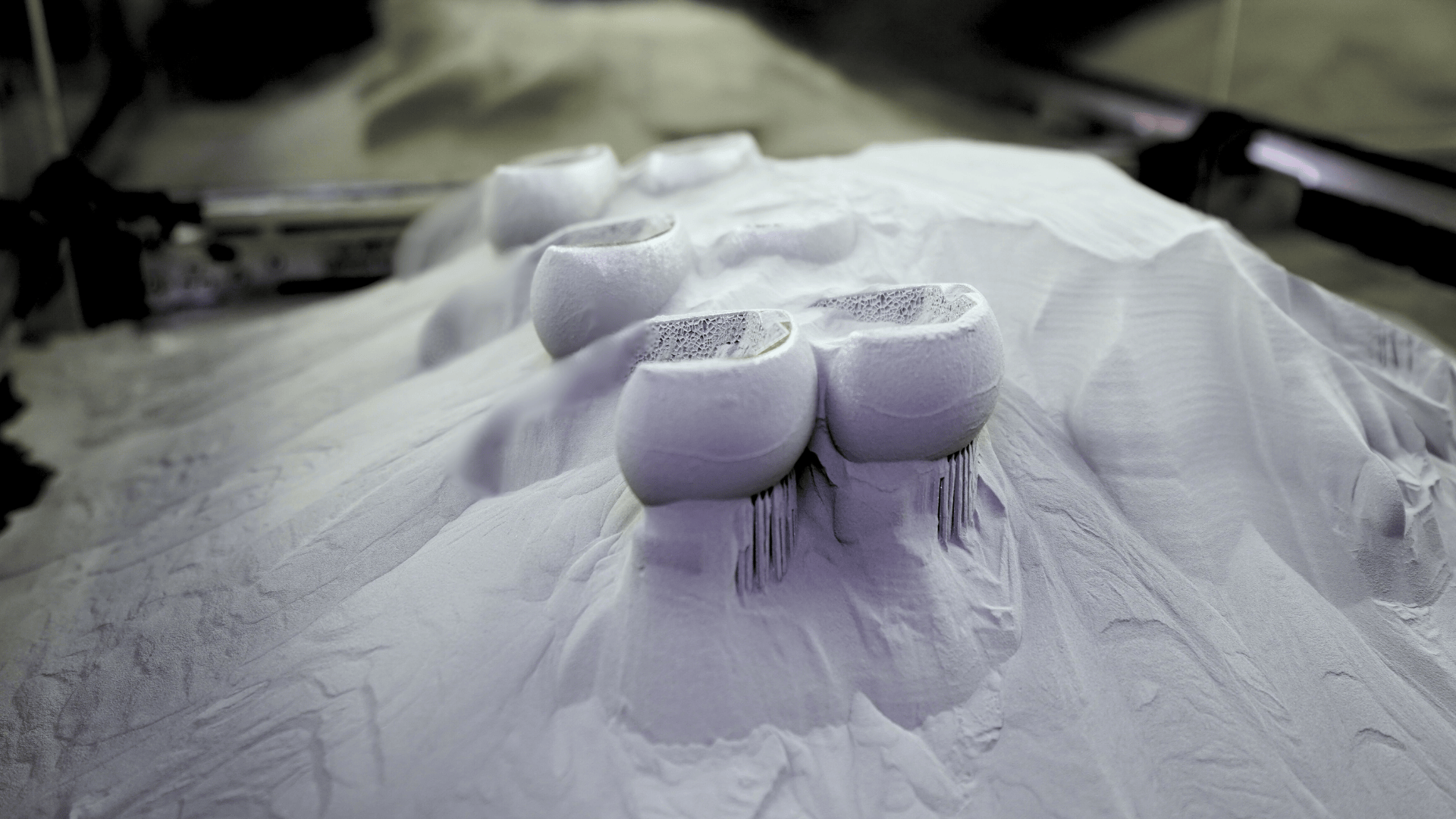

6. Surface Finishing

Depending on customer specifications, plates may undergo mechanical polishing or bead blasting to achieve the desired surface roughness. This step is key for aesthetic appearance and adhesion consistency during anodising.

7. Colour Anodising

Anodising enhances the oxide layer on titanium, improving corrosion resistance and providing colour differentiation between plate sizes or configurations. The process involves immersing plates in an electrolyte bath where controlled voltage determines oxide thickness and colour outcome. Common hues include blue, gold, and purple, each achieved without dyes. The anodised surface is fully biocompatible and supports long-term performance.

Key Benefits of Anodising:

Improved corrosion and wear resistance

Biocompatible, non-toxic oxide layer

Harder and more durable surface

Functional colour coding for easy intraoperative identification

Key Insight:

The anodising stage not only improves corrosion resistance but also adds a practical dimension to surgical efficiency through consistent, permanent colour coding.

8. Laser Marking

Once anodised, each bone plate receives a permanent laser marking that includes traceability information such as part number, batch code, and manufacturer ID. Laser marking ensures compliance with Unique Device Identification (UDI) requirements without affecting the surface integrity.

9. Cleaning

All parts undergo precision cleaning to remove residual oils, particulates, or process contaminants. Ultrasonic cleaning and high-purity rinses ensure the surfaces meet cleanliness standards required for medical implants.

10. Inspection & Release

Inspection combines dimensional metrology, surface analysis, and visual checks. Coordinate Measuring Machines (CMMs) verify geometric accuracy, while optical inspection ensures consistency in anodised finishes. Only components meeting all criteria progress to final release.

11. Non-Sterile Bag & Label

Finally, the plates are packaged in non-sterile barrier bags with clear labelling for traceability and storage. This format suits OEM customers who will later perform in-house sterilisation.

Precision and Process Control

Every process in the bone plate manufacturing workflow is designed for process stability. Our in-house capabilities allow for complete control over machining, surface treatment, and inspection. This vertical integration reduces lead times and ensures each plate meets specification at the first pass.

Quality management systems aligned with ISO 13485 govern documentation, validation, and risk management throughout the process. Statistical process control (SPC) tools monitor critical parameters such as surface roughness, anodic thickness, and dimensional variation.

The Role of Surface Engineering in Implant Success

Beyond structural performance, the surface of a bone plate strongly influences its biological response. Smooth, well-anodised surfaces minimise friction against soft tissues and reduce bacterial adhesion risk. Controlled surface roughness also supports better fixation outcomes in certain designs, depending on clinical application.

By offering in-house anodising, Croom Medical ensures consistency between mechanical and surface properties, eliminating potential variability that can occur when these steps are outsourced.

Conclusion

Titanium bone plate manufacturing is a tightly controlled process that transforms certified titanium alloy into a biocompatible, precision-engineered implant. Each step, from raw material verification to anodising and inspection, is critical to performance and patient safety.

At Croom Medical, we integrate CNC machining, surface finishing, and anodising under one roof to deliver titanium bone plates that meet stringent orthopaedic standards and customer specifications.

Looking for expert guidance on your next titanium bone plate manufacturing project? Whether your requirements involve custom geometries, colour-coded anodising, or complete process validation, Croom Medical has the expertise and technology to deliver exceptional results.

Connect with our highly experienced orthopaedic manufacturing team today.