Finishing & Polishing

Proven, high-quality

surface finishing.

CAPABILITIES

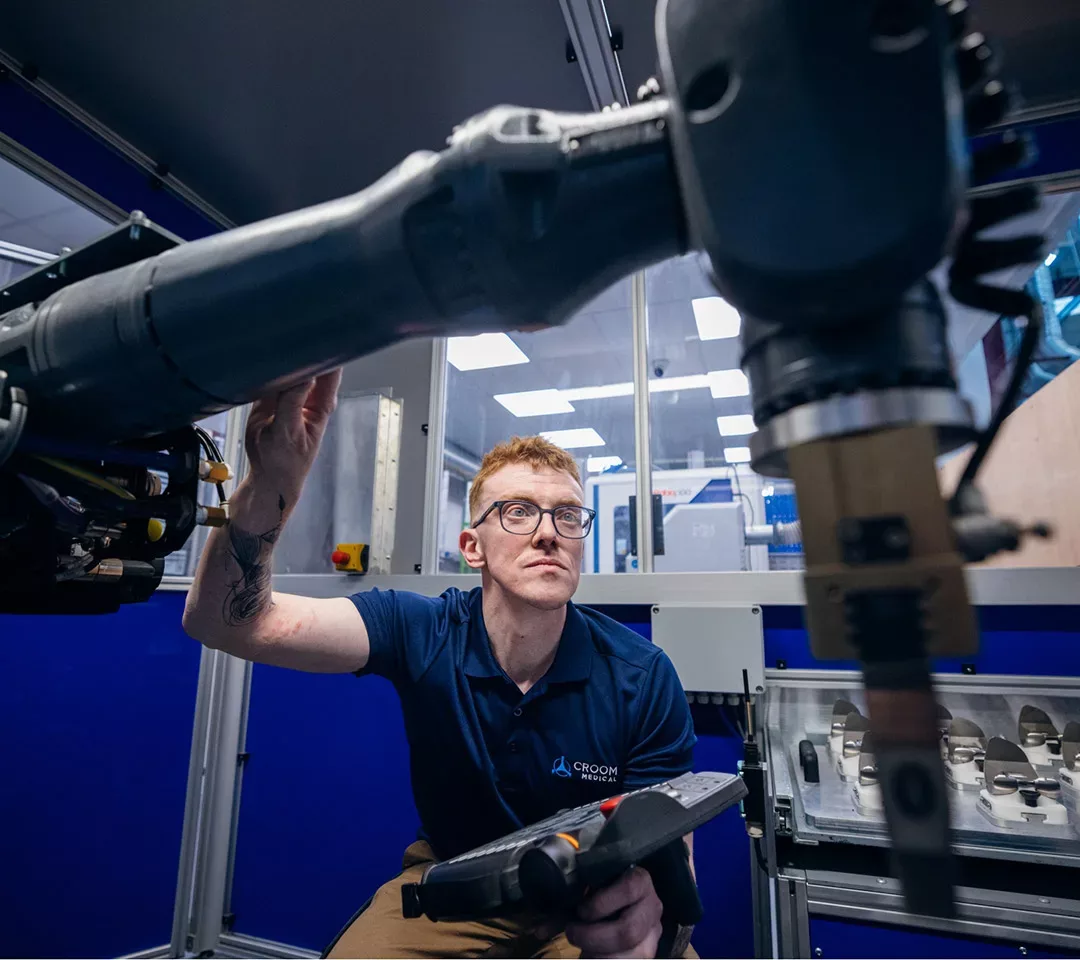

Automation led.

Our state-of-the-art facilities and advanced technologies enable us to deliver high-quality surface finishing that meets the stringent requirements of the medical industry. Backed by automated robotic finishing led by our internal automation team, we also collaborate with academic partners to push the boundaries of surface finishing, and are committed to continued investment in the latest technologies.

- Skilled Hand Polishing

- Mass Media Finishing / Drag Finishing (Ceramic, Plastic and Nutshell)

- Robotic Polishing

- Media Blasting

- Stoning

- Automated Electro Polishing

- Shot Peening & Bead Blasting

- Deburring

- Heat Treatment

- CNC Laser Marking

- Surface Texturing and Patterning

Automated Surface Finishing

For precise, accurate finishing

Our dedicated automation team utilise advanced robotics and automated surface finishing technologies to deliver high-quality and consistent finishing for our orthopedic implants. We employ a range of surface finishing techniques, including electro-polishing, blasting, and grinding. Our state-of-the-art robotics systems enable us to perform precision surface finishing on cast implants, ensuring that each product meets the highest standards of quality and consistency.

Capabilities

Joint Partnership

We help drive progress for our medical device customers by enhancing both their production capacity and their product and process innovation.

Manufacturing Capabilities

The facilities, technologies and processes to deliver end-to-end manufacturing.

Value-Add Capabilities

The team, expertise, and ingenuity to drive tangible added-value for our customers.