Trauma & Extremities

Upper and lower extremity

replacement and fixation.

Precise components and biocompatible materials.

A wide range of orthopedic implants and instruments for upper and lower extremity joint replacement and fixation, as well as for finger and toe replacements. Our manufacturing expertise includes advanced machining and polishing techniques for precise components and biocompatible materials for durability.

For upper extremity replacements, we provide elbow, shoulder, finger, and wrist replacements, as well as fixation options. For lower extremity replacements, we provide ankle and toe replacements, as well as foot and ankle fixation. Our range of instruments includes reamers, drivers, guides, broaches, rasps, drills, blades, taps, burrs, and trials. Implant options include screws, baseplates, nails, pins, stems, and glenoids.

Shoulder & Elbow

High-quality, durable implants

High-quality shoulder and elbow joint replacement implants for OEM companies, featuring biocompatible materials known for their exceptional durability.

Our elbow replacements effectively relieve pain and restore joint function in patients with damage. Our shoulder replacements prioritise mobility and pain reduction, while our finger replacements are designed to alleviate pain and restore function for individuals with finger joint damage.

Foot & Ankle

Custom foot and ankle solutions

We work closely with our OEM customers to develop customised, high-quality, ankle and foot implants that meet their unique needs. Products include ankle fusion plates, total ankle replacement systems, and foot plates, all made from high-strength materials such as titanium, tantalum, and cobalt chrome. We manufacture implants with exceptional biomechanical support and stability, promoting faster healing times and reducing the risk of complications.

Tibia & Femur

High-strength, precise implants

We manufacture tibia and femur implants using advanced technologies such as CNC machining, robotic finishing, media blasting, laser marking, and automated inspection. Our detailed process begins with the design and development of the implant using CAD software, followed by CNC machining of the implant from high-strength materials such as titanium, tantalum, or cobalt chrome. Robotic finishing and media blasting prepare the implant’s surface for further processing, and laser marking ensures traceability. Automated inspection techniques guarantee that every implant attains the highest standards of precision and excellence.

Hand & Wrist

Unparalleled support and stability

A wide range of hand and wrist implants, featuring advanced materials such as titanium, tantalum, and cobalt chrome known for their high strength. Our commitment to tailored solutions ensures the delivery of implants that not only meet but exceed biomechanical standards, providing unparalleled support and stability.

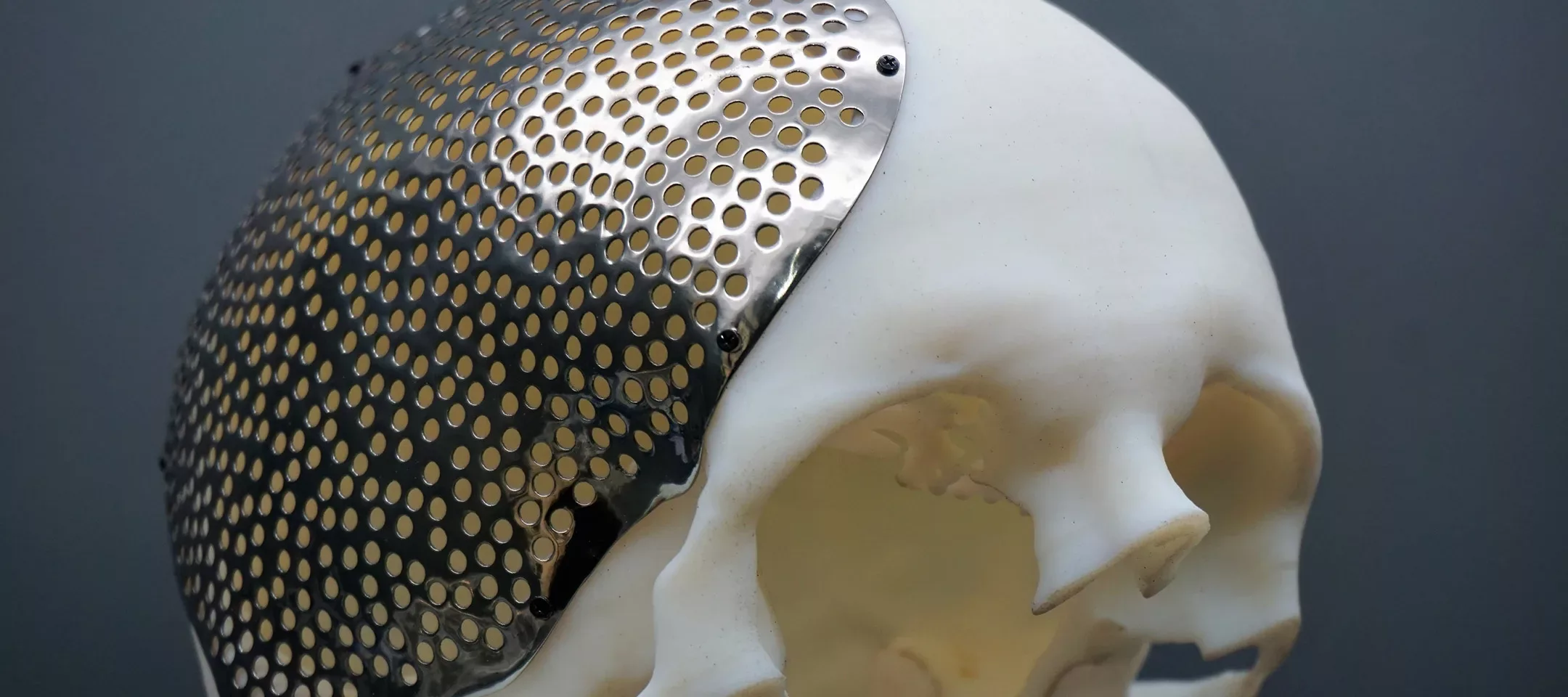

Cranial & maxillofacial

Personalised, patient-specific implants

Additive manufacturing is revolutionising the medical industry, enabling the design and manufacture of custom medical devices that are both efficient and cost-effective for the patient. We specialise in manufacturing a range of patient-specific implants tailored for cranial and maxillofacial applications. These implants are precisely crafted for individual patients, taking into account their unique anatomy, specific pathology, and the surgeon’s preferences regarding design, fixation solutions, and materials. This approach ensures a highly personalised and precise outcome, ultimately contributing to improved patient outcomes and advancing the field of medical technology.

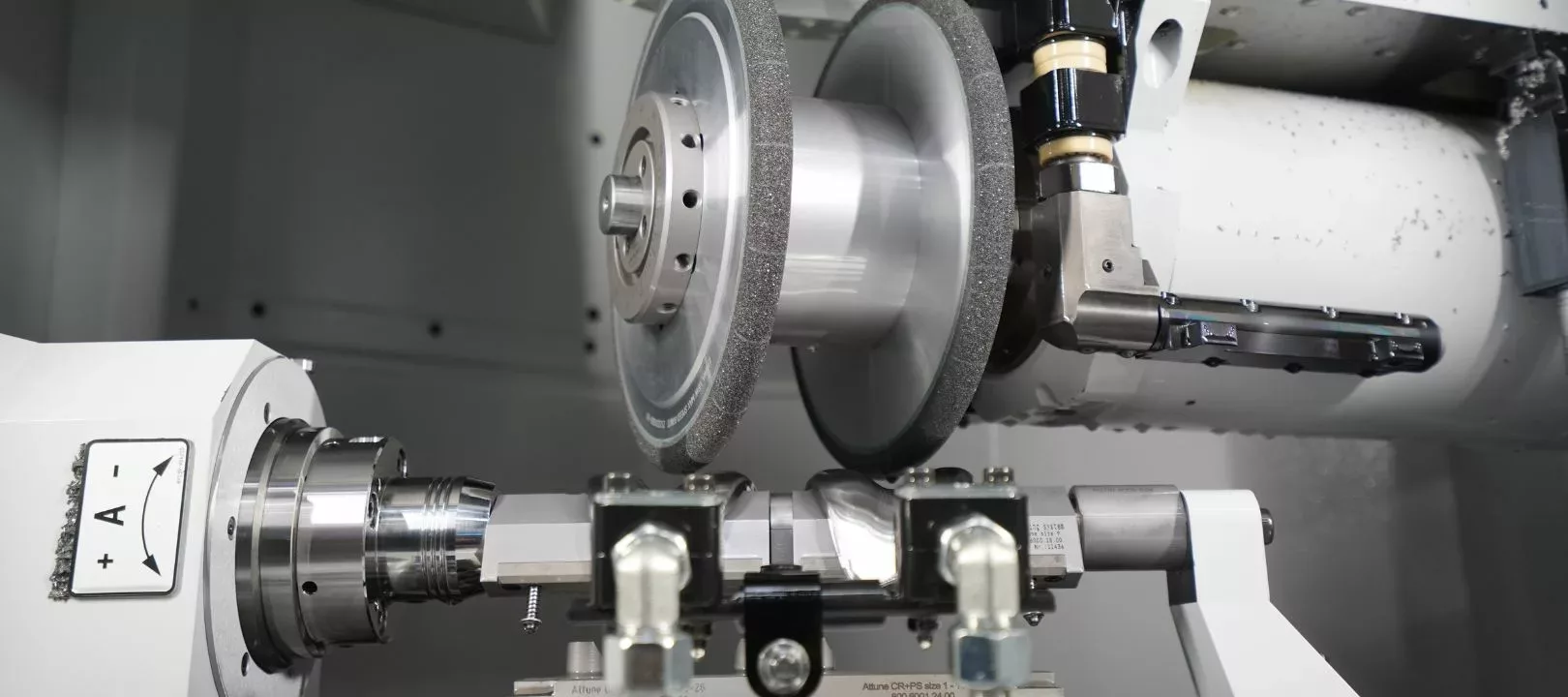

Manufacturing Capabilities

Leverage our agility, ingenuity, automation and low-cost base to drive down your cost of manufacture. We foster a culture of curiosity and exploration, continually invest in the latest technologies and closely collaborate with our customers to drive sustained material and process innovation. Our capabilities and machinery include the following:

Manufacturing Technologies

- DMLS/SLS Additive Manufacturing

- 5-axis CNC Milling & Grinding

- 12-axis CNC Swiss Auto-Turning

- 3-axis CNC Surface Grinding

- Wire & Sinker EDM (Electro Discharge Machining)

- ECM (Electro Chemical Machining)

- CNC Laser Cutting and Welding

- Photochemical Etching

- Welding

Cleaning & Finishing

- Skilled Hand Polishing

- Mass Media Finishing / Drag Finishing (Ceramic, Plastic and Nutshell)

- Robotic Polishing

- Media Blasting

- Stoning

- Automated Electro Polishing

- Shot Peening & Bead Blasting

- Deburring

- Heat Treatment

- CNC Laser Marking

- Surface Texturing and Patterning

- Automated ultrasonic cleaning

Quality Control

- Non-destructive Testing: Fluorescent Penetrant Inspection (FPI) Line

- CMM

- SEM

- X-Ray

- Optical Gauging Products (OGP)

- Visual Inspection

- Hardness Testing

- Mechanical Testing – tensile, compression, and fatigue testing

- Surface Roughness and Finishing Inspection

- Vision Systems

- Software Development Leveraging Artificial Intelligence (AI)

Committed To Excellence

Croom Medical is committed to maintaining an effective quality management system to ensure compliance with all applicable quality and regulatory requirements, through continual improvement. We share a commitment to long lasting relationships based on trust, by partnering with our customers.

Fully Certified

DEVICES

Extend capacity & advance quality

Tap into our passion for innovation and we’ll help advance quality, extend your capacity and accelerate time to market.