Additive manufacturing (AM) has reached a level of maturity where it is no longer viewed purely as a novel innovation. For orthopaedic OEMs, it is becoming a practical and cost-effective manufacturing strategy. By embracing 3D printing, companies can shorten development cycles, reduce tooling costs, simplify inventory, and enable production of complex geometries that conventional machining cannot achieve.

At Croom Medical, we see AM not as a competitor to machining, but as a complementary technology. Used correctly, it can unlock both immediate cost savings and long-term performance improvements for implants.

Measuring the True ROI of Additive Manufacturing

The initial investment in AM equipment, validation, and expertise can feel significant. However, the returns often outweigh the upfront cost when considering the broader programme efficiency. Faster prototyping, fewer design iterations, reduced tooling spend, and streamlined regulatory submissions all contribute to a compelling business case.

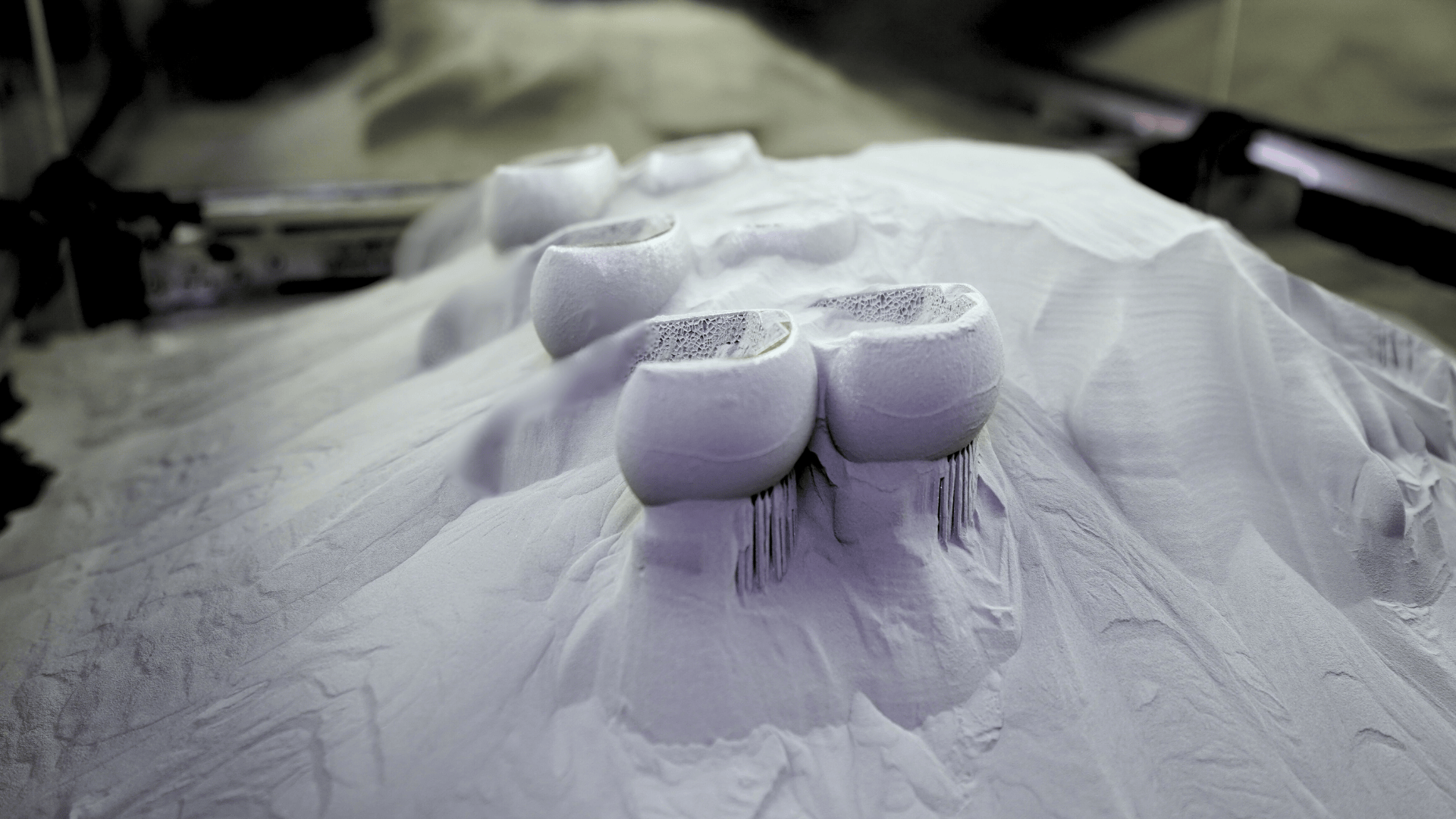

Traditional machining may be more cost-effective for high-volume, simple components such as bone screws. Yet when implants demand porous structures, complex geometries, or intricate surface features, AM delivers unique value. Printing the solid and porous regions of an implant in a single build eliminates the need for secondary coating steps, consolidating processes while reducing cost and lead time.

Key Insight: Additive manufacturing is most cost-effective where complexity is high and volumes are modest, enabling OEMs to achieve both performance and efficiency gains.

Saving Time Across the Development Cycle

Time is often the most valuable commodity in orthopaedics. AM accelerates every stage of the design cycle, from prototyping to validation and through to production. With CAD-driven iteration, OEMs can test multiple design revisions in weeks rather than months.

In production, AM’s ability to consolidate processes eliminates the need for multiple suppliers and tooling setups. At Croom Medical, we have demonstrated this by converting implants once manufactured through casting, machining, and plasma coating into single-step printed builds at equivalent costs but with significantly reduced timelines.

A shoulder implant, for example, can be printed in just days compared with the month-long machining process required for wrought material. This speed translates directly into earlier verification testing and quicker regulatory pathways.

Materials, Tooling, and Inventory Simplification

Conventional subtractive manufacturing depends on stocking a wide range of billets, bars, and cannulations, each with long lead times. AM simplifies this by relying on a standardised titanium powder feedstock, supported by argon and electricity.

Although powder carries a higher cost per kilogram, its flexibility reduces the burden of carrying inventory in multiple forms and sizes. More importantly, tooling costs are slashed. Where every new machined part might demand custom fixtures and jigs, AM can produce radically different geometries on the same printer with no hardware change.

Designing with AM principles in mind further minimises post-processing. By integrating lattice structures, internal channels, and porous surfaces into the print, additional machining or coating steps can be avoided entirely.

Personalising Implants Without the Cost Burden

AM is especially powerful in enabling patient-specific implants and short-run production. Printing to demand reduces inventory risk, allowing OEMs to order exactly what they need without tying up capital in stock.

Patient-specific solutions can be produced in days, supporting critical clinical cases with precision-fit implants. Moreover, mixed-build runs allow small quantities of different implant types to be combined on a single plate, delivering cost efficiency where traditional manufacturing would require expensive setups for each low-volume batch.

For runs under 200 parts, AM often proves more economical due to reduced tooling and setup requirements. This is a crucial advantage for OEMs balancing personalised care with cost management.

Unlocking Competitive Advantage

The true power of AM lies not just in cost savings but in the innovation it enables. By rethinking design around the possibilities of printing, entirely new implant mechanisms become feasible. At Croom Medical, we have partnered with customers to transform assemblies that were once restricted by machining limitations into streamlined printed solutions.

Deformable implants, integrated lattice structures, and novel fixation mechanisms are examples of breakthroughs made possible only by additive manufacturing. As process control continues to advance, costs will decline further, making AM an increasingly attractive route for orthopaedic innovation.

The companies that embrace AM today, investing in the knowledge and partnerships required to implement it effectively, will be the ones positioned to outpace competitors tomorrow.

Conclusion

Additive manufacturing is no longer an experimental option in orthopaedics. It is a proven enabler of faster design cycles, lower tooling costs, simplified supply chains, and personalised implant solutions. More importantly, it unlocks new design freedoms that enhance implant performance and patient outcomes.

Looking for expert guidance on your next joint replacement implant manufacturing project? Whether your project involves large-scale production or custom, high-complexity implants, Croom Medical has the expertise and technology to deliver superior results.

Connect with Croom Medical’s highly experienced joint replacement implant manufacturing team for tailored solutions and industry-leading expertise. Contact us today.