Why Bone Screws Are More Complex Than They Look

In orthopaedics, bone screws do a lot of heavy lifting for something so small. They hold fractures together, secure plates in place, and anchor implants in bone. They have to do all this while meeting strict regulatory standards, fitting perfectly with mating components, and performing under real-world loads in the body.

From a manufacturing perspective, it’s a balancing act. The screws need to be strong but not brittle, sharp enough to cut into bone without damaging surrounding tissue, and consistent in every dimension, not just within a single batch, but across years of production. When you scale that up to thousands of screws in multiple sizes, the challenge becomes delivering that same precision every time.

The Turning Process & Getting It Right from the Start

At Croom Medical, most bone screws start life as medical-grade titanium or stainless steel bar stock, sourced from suppliers we know and trust. Traceability isn’t a box-ticking exercise. Every mill certificate and lot number matters when the final product is destined for the operating room.

We use advanced multi-axis CNC lathes and Swiss-type turning centres to shape the screw’s core geometry in a single setup. This approach keeps concentricity tight and avoids variation creeping in between operations. For cannulated screws, where the inner bore must align perfectly with the outer thread, we ream and finish the cannula before the threads are cut, holding tolerances that keep the screw sliding smoothly over a guide wire in surgery.

Surface Finish Matters

A bone screw’s performance isn’t just about its dimensions. Surface integrity plays a huge role in how it interacts with bone and tissue. Too rough, and you risk irritation; too smooth, and you lose the cutting efficiency needed for insertion.

We tune cutting speeds, feeds, and tooling to suit the material, aiming for clean edges and a flawless thread profile. For titanium, we keep a close eye on heat build-up to avoid work hardening, which can affect both performance and corrosion resistance. After machining, passivation and ultrasonic cleaning remove any residual particles or machining fluids, ensuring the screw is ready for downstream sterilisation.

Building Quality Into the Process

Quality control doesn’t just happen at the end of the line. In-machine probing, automated gauging, and optical inspection systems check critical dimensions during production. This gives us real-time data to make adjustments before a part goes out of tolerance.

Process validation follows a strict IQ/OQ/PQ framework, proving not only that we can make a part to spec, but that we can do it repeatedly, shift after shift, batch after batch. It’s the only way to maintain tight tolerances when you’re running high volumes.

Scaling Without Slipping

Demand for bone screws can change quickly. A new implant system launches, or market demand spikes. Our production is designed to scale without sacrificing quality. Quick-change tooling and flexible scheduling let us move from small prototyping runs to large-scale production in days, not weeks.

For supply chain managers, this means fewer stock-outs, faster response to urgent orders, and the reassurance that a screw made in month one will be identical to one made in month twenty-one.

More Than Just Screws

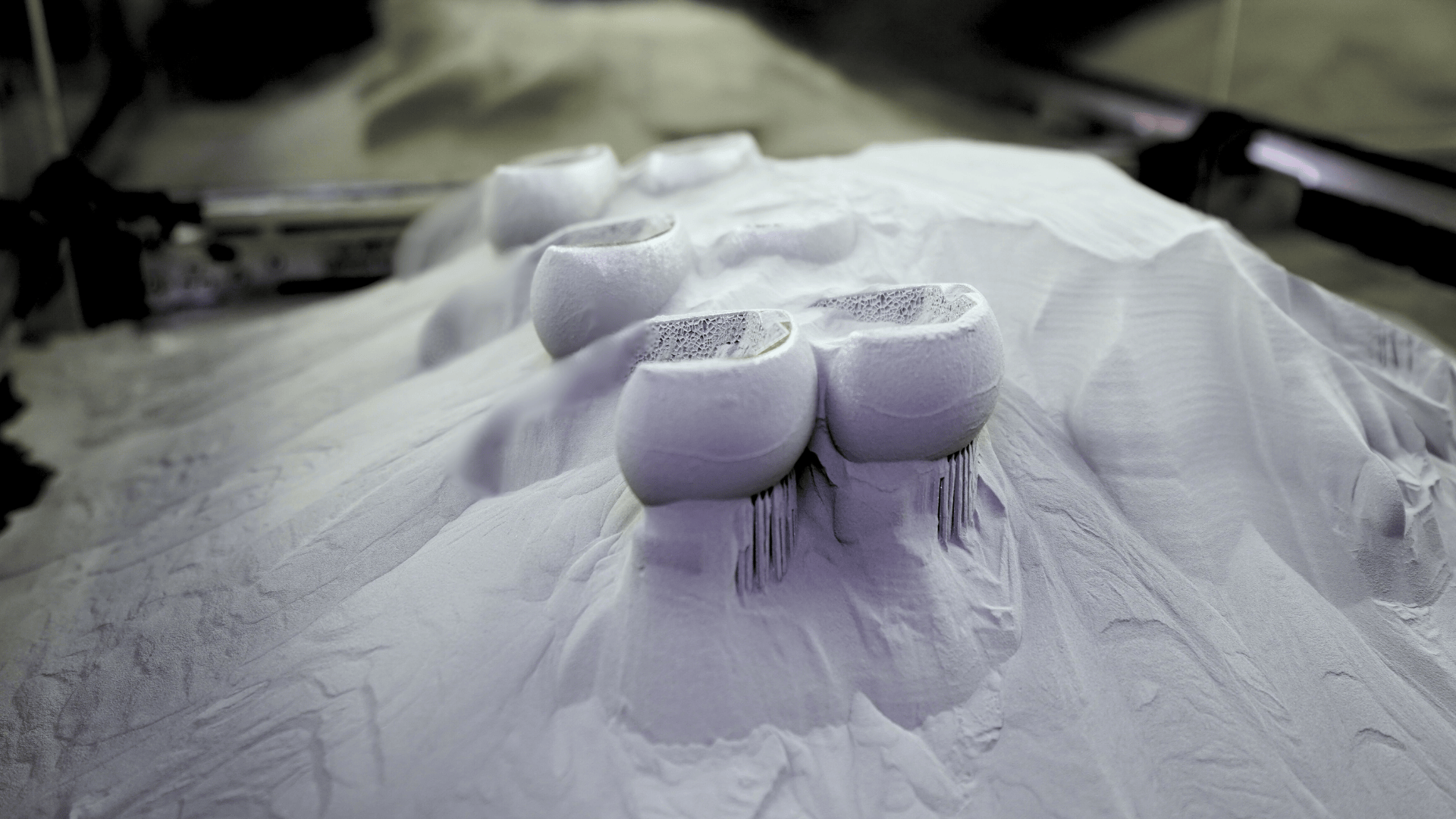

While bone screws are a big part of what we do, they’re not the whole story. Our facility is set up to make the plates, instruments, and porous structures that complete the system. By keeping all these processes in-house (CNC milling, turning, metal additive manufacturing, and finishing) we cut down on lead times, reduce supplier complexity, and make it easier to validate a complete product line through one partner.

The Bottom Line

Making bone screws at scale isn’t just about knowing how to run a CNC lathe. It’s about understanding the clinical role of the part, engineering it for performance, validating the process, and building the capacity to deliver without compromise.

That’s the standard we work to at Croom Medical, tight tolerances, consistent quality, and the ability to deliver at any scale, every time.