Manufacturing a femoral head, the spherical “ball” component of a hip implant, is a complex journey that demands extreme precision. These orthopedic implants must meet stringent tolerances and surface finish requirements to ensure long-term performance inside the human body. For example, a femoral head’s sphericity may need to be within ±0.004 mm to avoid excessive wear in the joint. Achieving this level of accuracy and mirror-like smoothness requires advanced CNC machining, careful planning, and thorough quality control.

In this article, we explore the end-to-end manufacturing process of a femoral head, focusing on the challenges of machining AISI 316L stainless steel and CoCrMo (cobalt-chrome-molybdenum) alloy. We’ll discuss developing 5-axis mill-turn programs for a family of implant sizes, designing high-throughput fixtures and robotic polishing systems, executing rigorous Performance Qualification (PQ) protocols, and using CMM inspection programs to ensure every critical feature meets specifications. Throughout this journey, we highlight how Croom Medical leverages these practices to deliver high-quality femoral heads and lead the way in orthopedic implant manufacturing.

Femoral Head Material Challenges: AISI 316L vs CoCrMo

The femoral head is typically made from biocompatible alloys like AISI 316L stainless steel or cobalt-chromium-molybdenum (CoCrMo). Each material brings distinct manufacturing challenges. 316L stainless steel has been used in implants for decades due to its corrosion resistance and strength. However, it was largely replaced by CoCrMo alloys for high-wear hip joint components because early stainless steel heads suffered from friction and wear issues. CoCrMo, by contrast, offers superior wear resistance and high hardness, making it ideal for femoral heads and other bearing surfaces. In fact, CoCrMo femoral heads are renowned for their durability and low friction in metal-on-polyethylene or metal-on-metal joints.

The trade-off is that CoCrMo is notoriously difficult to machine, as a casting, it can exceed 50 HRC in hardness, with poor thermal conductivity, placing it “among the most difficult to machine” materials. Cutting tools wear quickly, and machining must be carefully controlled to avoid heat buildup. 316L is softer (around 79 HRB in annealed form) and easier to cut, but still requires careful process optimization to achieve the necessary surface quality and dimensional accuracy. Both materials demand robust CNC programming, proper tooling, and polishing to meet orthopedic-grade standards.

Key Insight

The material choice influences the CNC machining strategy, from toolpath design to cutting speeds and tool materials, and necessitates an integrated approach to finishing and quality control.

5-Axis Mill-Turn Programming for Precision

Producing a perfectly spherical femoral head with a tapered recess (to attach to the hip stem) is a multi-faceted machining challenge. Croom Medical employs 5-axis mill-turn CNC machines to perform both lathe turning and 5-axis milling in one setup, enabling efficient manufacturing of these complex parts. The CNC programming must be meticulous: tool paths are optimized to cut the spherical geometry evenly and to bore the taper at precise angles and depths for various neck length options.

By developing a family of programs (or a single parametric program) that accommodates all femoral head variants, the machining process can be standardized across different diameters and neck lengths. This family-of-parts programming approach maximizes consistency and reduces setup time when switching between, say, a standard 28 mm diameter head with a short neck and a 32 mm head with a long neck.

The result is a highly efficient CNC machining stage, one that lays the foundation for downstream finishing and inspection.

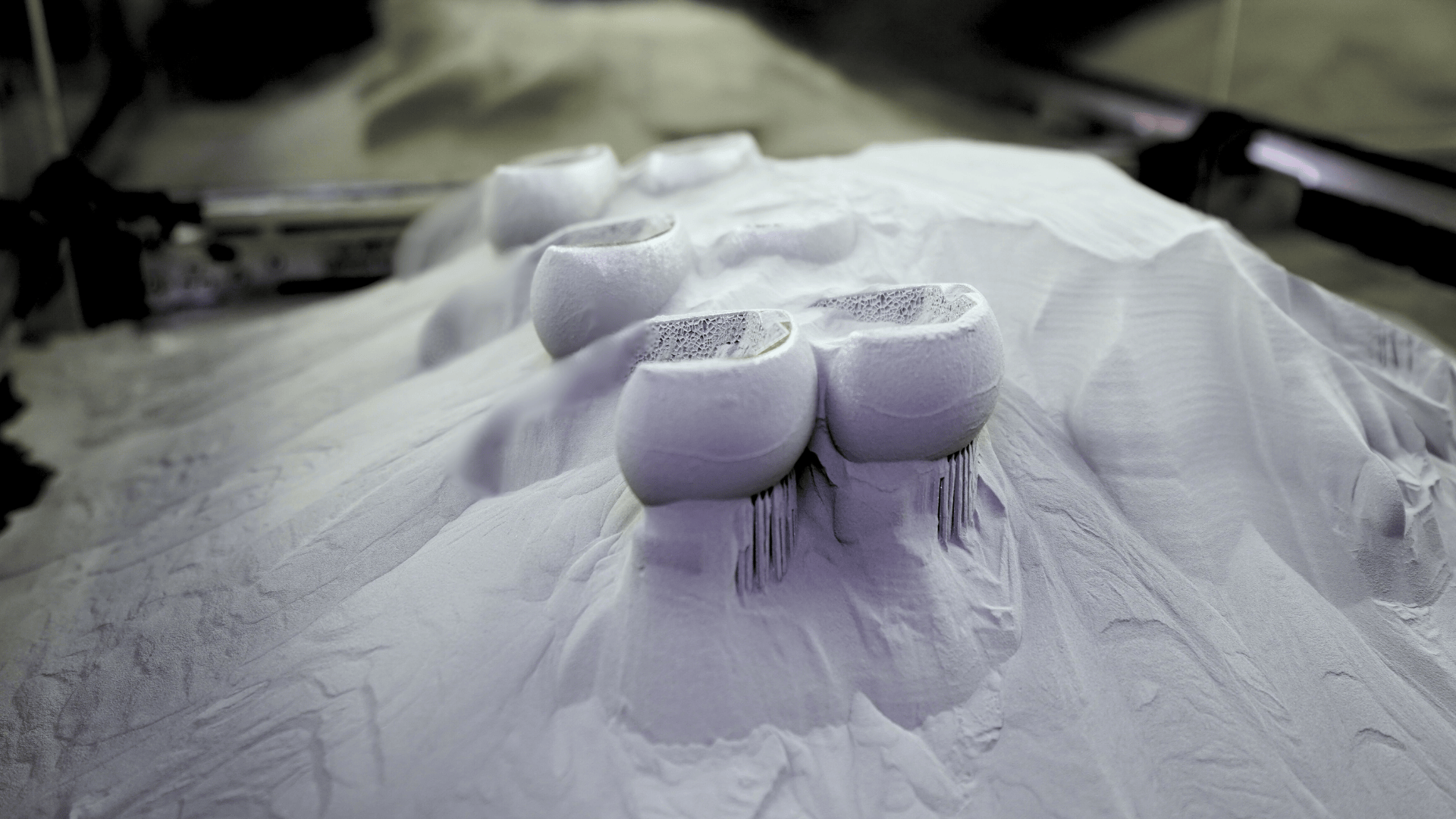

High-Throughput Fixturing and Robotic Polishing for Femoral Heads

Even the best CNC machining often isn’t the end of the journey, femoral heads require polishing to achieve their final mirror finish. At Croom Medical, we tackle this with specially designed fixtures and automated polishing systems. First, the challenge is how to securely hold a nearly spherical part during both multi-axis machining and polishing. Our engineers developed common, high-throughput fixtures that can locate the femoral head via its internal taper or another datum, clamping it firmly without marring the critical spherical surface.

After machining, the same or a similar fixture design can be used to hold the part for polishing processes, whether in a robotic cell or a drag-finishing system. Robotic polishing has been a game-changer in implant manufacturing. Traditionally, highly skilled technicians would polish femoral heads by hand, using abrasive pastes and lots of elbow grease. This manual process, however, is slow and can introduce inconsistencies, two parts might not end up with the exact same finish or geometry.

Croom Medical leverages automated surface finishing technologies such as robotic buffing arms, abrasive flow machines, and even automated electro-polishing, to achieve a flawless finish repeatably.

Validating the Process with IQ/OQ/PQ

In the medical device industry, making a flawless implant once is not enough. You must prove that your manufacturing process can consistently produce in-spec products. Croom Medical adheres to ISO 13485 and FDA quality system regulations, which mandate thorough process validation. For a new femoral head machining process (especially when covering a whole product family), we perform Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) as part of validation.

The critical final step is PQ, where we run multiple consecutive batches under normal conditions to demonstrate the process yields acceptable parts consistently. A common requirement for PQ in medical machining is to manufacture at least three full batches and show that all critical dimensions and properties meet the specifications repeatedly.

Key Insight

Rigorous validation ensures that femoral heads are consistently manufactured to specification, providing quality assurance to both the manufacturer and healthcare providers.

Unified CMM Inspection for All Critical Features

After machining and polishing, every femoral head must undergo thorough inspection before it ships. Given the tiny tolerances involved, Coordinate Measuring Machines (CMMs) are the workhorses of our quality assurance. One of the efficiencies we employ at Croom Medical is developing a unified CMM program that can be used to inspect the entire femoral head product family.

The CMM checks all critical features of the femoral head. Key measurements include the outer diameter of the spherical head, the form accuracy of the sphere, and the geometry of the internal taper. By combining cutting-edge metrology with intelligent programming, Croom Medical ensures that each femoral head leaving our facility is a replica of the last in terms of quality.

Conclusion

The journey of a femoral head from raw material to finished implant is a testament to advanced manufacturing and rigorous quality assurance. Starting with savvy CNC programming on 5-axis mill-turn machines, the process leverages automation and deep expertise to handle challenging materials like CoCrMo and 316L. Custom high-throughput fixtures and robotic polishing ensure that each implant achieves the flawless surface needed for smooth articulation. A strict validation regime (IQ/OQ/PQ) under ISO 13485 guidelines proves that this process can deliver consistent results for every size and neck configuration in the product family. Finally, unified CMM inspection and a suite of metrology tools verify every critical feature, from diameter to surface finish, so that surgeons can trust these components in life-changing hip replacement procedures.

By integrating all these steps, Croom Medical has created a world-class manufacturing solution for orthopedic implants. Whether it’s pioneering the use of new materials or refining the CNC journey of a femoral head, Croom Medical remains committed to excellence at every step. This holistic, cutting-edge approach ultimately benefits the patients who receive these implants, ensuring they receive an implant that will perform reliably and last for decades inside the human body.

About Croom Medical

Croom Medical is a precision manufacturing company specialising in high-quality orthopedic implants. With advanced CNC machining, additive manufacturing, and robotics expertise, we support OEMs in producing superior femoral heads, knee systems, and spinal implants. Contact us to learn more about our capabilities and how we can help with your next project.