Orthopaedic implant manufacturers increasingly seek partners who can deliver complete surface finishing solutions under one roof. The integration of hydroxyapatite (HA) and titanium (Ti) plasma-spray coatings within a single Irish facility represents a major step forward in process efficiency, traceability, and performance assurance for medical device OEMs.

By combining these coating technologies alongside precision machining, we provide OEMs with a vertically integrated pathway from raw component to fully coated implant, streamlining validation, quality control, and lead time management.

Why Surface Coatings Matter in Orthopaedic Implants

Surface coatings are central to the performance of orthopaedic implants. They influence osseointegration, corrosion resistance, and mechanical fixation at the bone–implant interface. When properly applied, coatings can improve implant longevity and reduce the risk of revision surgery.

The Function of Titanium Plasma-Spray Coatings

Titanium plasma-spray coatings create a roughened surface that promotes mechanical interlocking with bone tissue. Using plasma-spray deposition, molten titanium particles are propelled at high velocity onto the implant surface, where they rapidly solidify into a dense, adherent layer. This layer provides:

- – High surface roughness for bone fixation

- – Strong metallurgical bonding

- – Enhanced corrosion resistance

Moreover, titanium coatings serve as an excellent base layer for further functional coatings such as hydroxyapatite.

The Role of Hydroxyapatite Coatings

Hydroxyapatite, a calcium phosphate compound similar to human bone mineral, accelerates biological fixation. When plasma-sprayed onto a titanium or cobalt-chrome substrate, it promotes direct bone apposition and early osseointegration.

Key benefits include:

- – Improved bioactivity and bone bonding

- – Reduced healing times

- – Enhanced stability in load-bearing applications

When applied over a titanium bond layer, HA coatings combine the mechanical strength of the metal with the bioactive properties of the ceramic.

Integrating Coatings Within a Single Manufacturing Site

Traditionally, orthopaedic components are machined at one site and then shipped to separate coating providers. This fragmented supply chain adds transport risks, lengthens lead times, and increases the potential for handling damage or contamination. Integrating HA and Ti plasma-spray coatings into a single, validated facility eliminates these inefficiencies.

Benefits of Co-Located Coating and Machining Operations

Enhanced Process Control: Each step, from machining to coating, is executed under one quality management system, ensuring consistent validation and documentation.

Reduced Lead Times: Eliminating inter-facility transport compresses manufacturing cycles and simplifies scheduling.

Improved Traceability: Complete device history is maintained within a single facility, simplifying audits and regulatory submissions.

Minimised Handling Risk: Components remain in a controlled environment throughout production, reducing the chance of surface contamination or damage.

Key Insight: Integrating coating and machining in one location strengthens both process reliability and supply chain resilience for OEM partners.

Technical Foundations of Plasma-Spray Coatings

Both titanium and hydroxyapatite coatings rely on plasma-spray technology, a process that uses a high-energy plasma jet to melt coating powder and deposit it onto a prepared substrate.

Step 1: Substrate Preparation

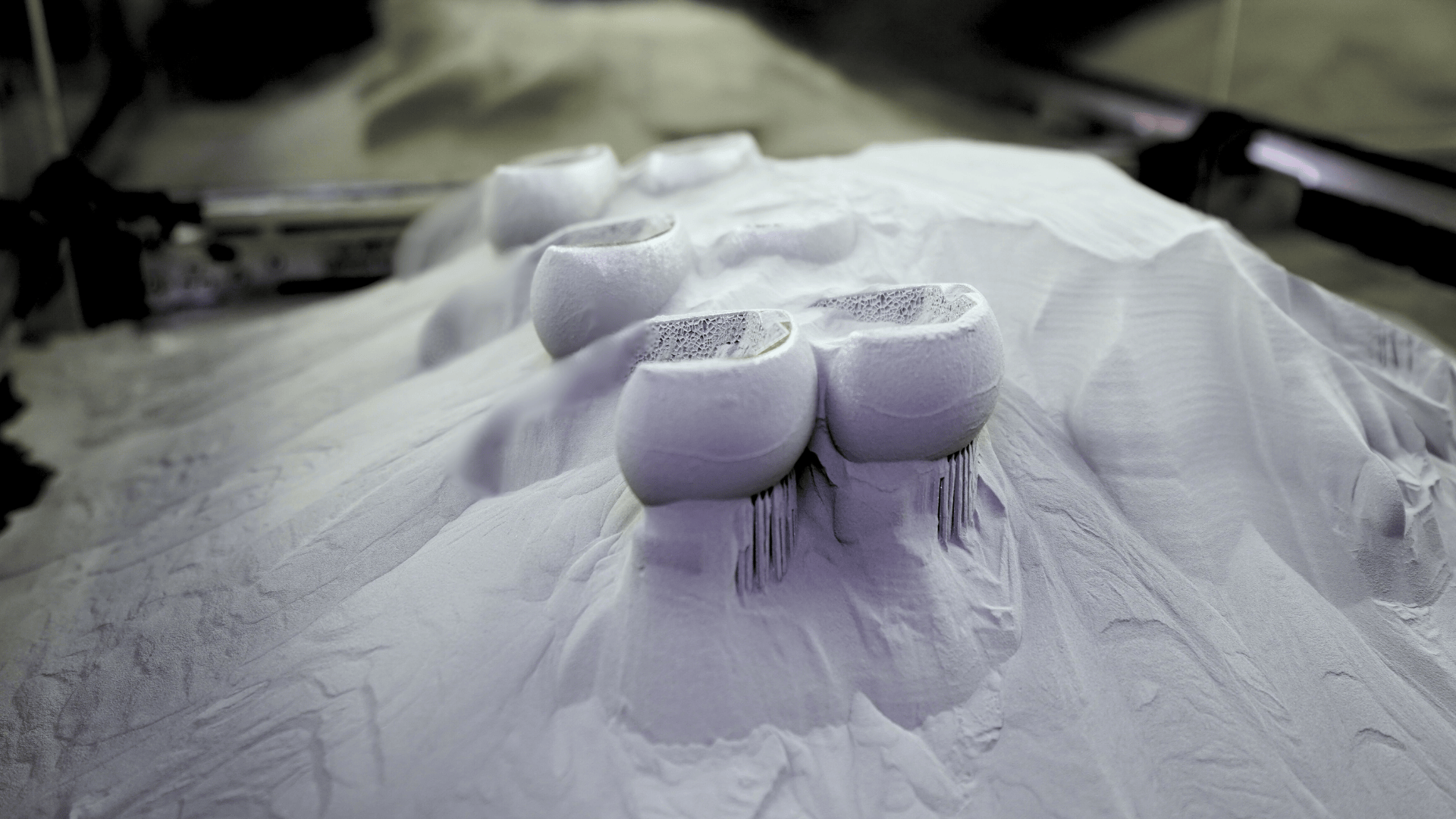

Proper surface preparation is essential. Components are grit-blasted, ultrasonically cleaned, and pre-heated to ensure optimal coating adhesion. The substrate’s surface topography directly affects the coating’s mechanical bond strength.

Step 2: Titanium Bond Layer Deposition

For HA-coated implants, a titanium bond layer is typically applied first. It acts as a mechanical anchor, improving adhesion and providing a chemically compatible transition layer between the metal substrate and ceramic top coat.

Step 3: Hydroxyapatite Top Coat

The HA powder is plasma-sprayed in a controlled atmosphere. Process parameters such as plasma energy, spray distance, and cooling rate are precisely managed to achieve the desired crystallinity and thickness—factors that directly influence biological response.

Step 4: Post-Coating Heat Treatment and Inspection

Following coating, parts undergo thermal treatment to stabilise crystallinity and relieve internal stresses. Coating thickness, porosity, adhesion strength, and phase composition are verified using non-destructive and destructive test methods in accordance with ASTM and ISO standards.

Quality Control and Validation for Medical Implants

Coating processes for orthopaedic devices must operate within a fully validated and traceable framework. Integration within a single site enhances both regulatory compliance and process repeatability.

Process Validation and Monitoring

Design of Experiments (DoE): Used to define optimal plasma parameters.

Statistical Process Control (SPC): Ensures consistent coating thickness and density.

Regular Calibration: Verifies torch energy output and powder feed rate accuracy.

In-Process Testing and Final Verification

Coatings undergo inspection for adhesion, microstructure, and phase composition. Cross-sectional microscopy verifies uniformity, while surface roughness is measured to ensure it meets implant specification.

Sustainability and Operational Efficiency

Integrating coating technologies into one facility also supports sustainability objectives. By removing the need for inter-site logistics and packaging, overall carbon footprint and waste are reduced.

Lower Transport Emissions: Fewer shipping steps between machining and coating sites.

Reduced Scrap: Improved process coordination minimises rework.

Energy Efficiency: Centralised systems for dust extraction, plasma power, and thermal management improve overall operational efficiency.

Applications Across Implant Types

Integrated HA and Ti plasma-spray capabilities support a broad range of orthopaedic implant geometries and indications.

Hip Implants

For femoral stems and acetabular cups, coatings enhance bone integration and long-term stability. The combination of a Ti base layer and HA top coat provides both mechanical grip and biological affinity.

Knee Components

Tibial trays and femoral components benefit from titanium coatings that improve cementless fixation and distribute load evenly across bone interfaces.

Spine and Trauma Devices

Plasma-sprayed coatings on spinal cages and trauma plates improve initial fixation strength and bone ongrowth potential in challenging load environments.

The Irish Advantage: Building Integrated Capability Locally

By developing full in-country coating capability, Ireland strengthens its position as a European hub for orthopaedic innovation. For OEMs, partnering with an Irish facility that can deliver precision machining and plasma-spray coatings in one location reduces logistical complexity and supports regional supply resilience.

This approach aligns with global trends toward nearshoring and vertical integration, offering OEMs greater oversight, faster iteration cycles, and improved cost efficiency.

Future Developments in Coating Technology

Ongoing R&D is advancing coating performance through process optimisation and material innovation.

- Nano-structured HA Powders: Enhance bioactivity and resorption control.

- Gradient Coatings: Tailor mechanical and biological properties across the surface.

Additive Manufacturing Synergy: Plasma coatings can be applied directly onto 3D-printed substrates, combining design freedom with surface functionality.

These innovations will further expand what can be achieved in orthopaedic surface engineering.

Conclusion

Integrating HA and Ti plasma-spray coatings within a single Irish facility delivers stronger process control, faster throughput, and improved device traceability for orthopaedic OEMs. The combination of machining, coating, and inspection under one roof creates a more resilient and sustainable manufacturing model. As demand for high-performance orthopaedic implants continues to grow, integrated surface engineering will play a vital role in meeting quality, regulatory, and sustainability expectations.