Limerick, Ireland – 11 September 2025 – Croom Medical, a CDMO specialising in orthopedic implant technology, today announces the launch of Biofuse™, a 3D-printed porous ingrowth platform produced with Laser-Powder-Bed-Fusion (L-PBF) technology.

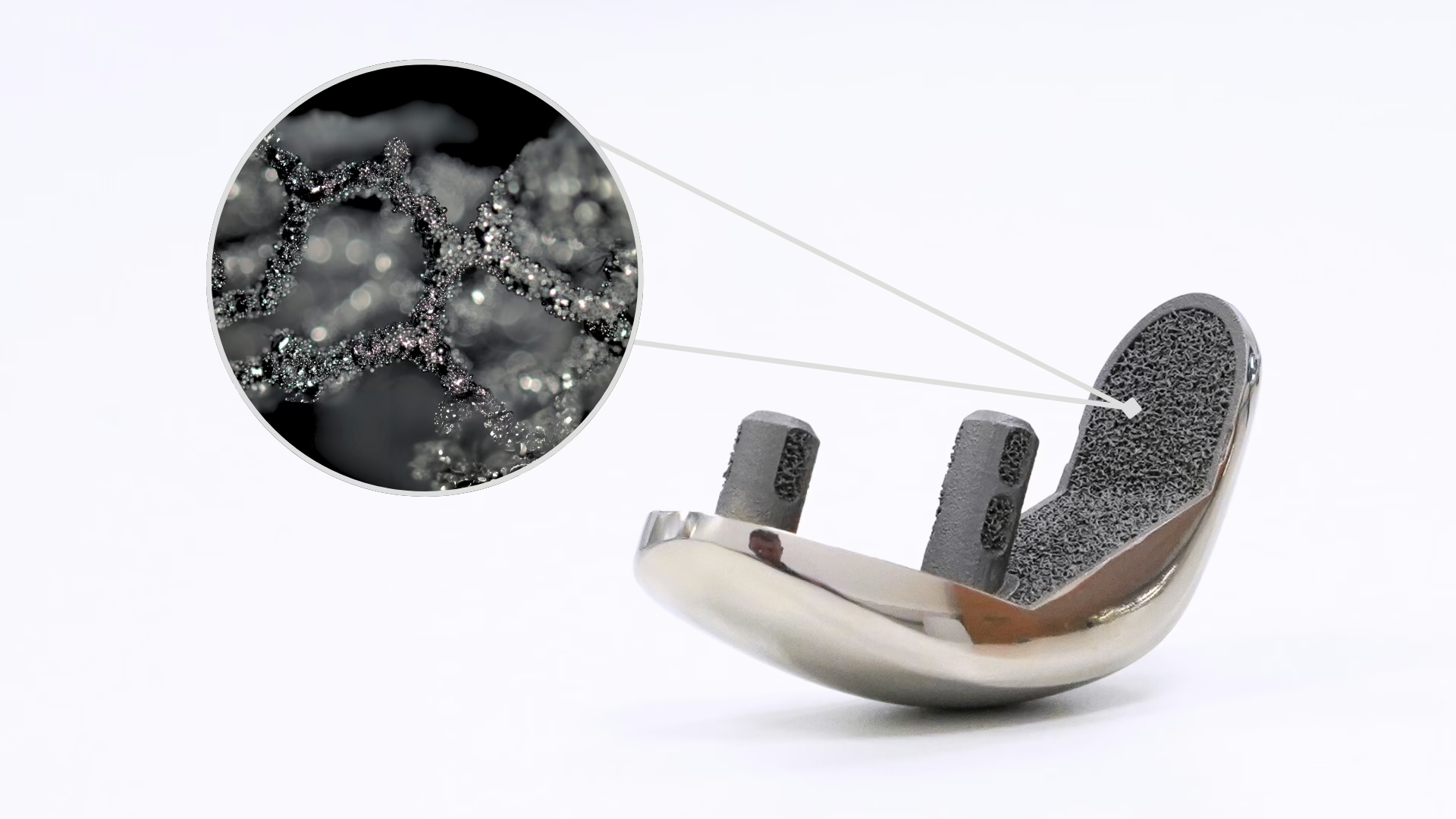

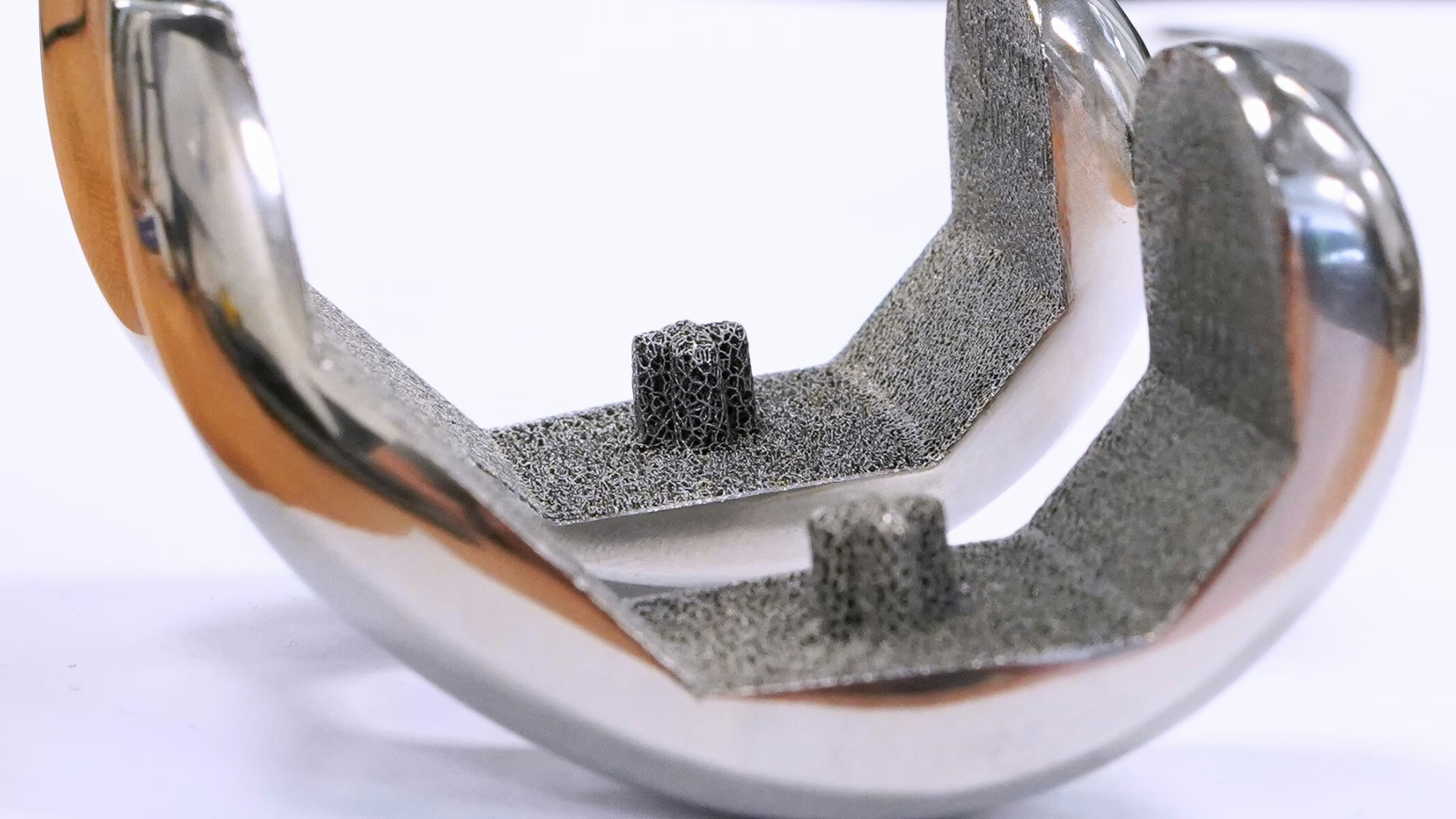

Biofuse™ integrates fully interconnected porous architectures directly into implant geometries, giving OEMs precise control over pore size, porosity, and lattice gradients. By combining dense and porous regions in a single build, it enables tailored ingrowth conditions while streamlining production and preserving feature fidelity.

Unlike traditional surface treatments such as spray coating or laser texturing, which provide only limited porosity, Biofuse™ forms its porous structures in-build across both surface and sub-surface regions. This eliminates delamination risks, removes coating and machining steps, and ensures structural integrity and consistent quality, even in complex geometries. The result is a more predictable path from design transfer through to validated production, helping OEMs accelerate development and deliver implants with enhanced performance.

Partial Knee Implant with Biofuse™ 3D-Printed Lattice Structure manufactured using Laser-Powder-Bed-Fusion technology in Ti64 Grade 23.

“Biofuse™ draws on our additive experience, where we’ve seen firsthand how components can be both faster and more cost‑effective to print than to machine,” said Sean McConnell, Engineering & NPI Manager at Croom Medical. “Embedding lattice structures directly into the build removes coating and machining steps. The result is a more predictable manufacturing process that consolidates production, preserves structural integrity, and helps OEMs bring implants to market faster.”

Backed by peer-reviewed studies, patents, and ongoing R&D, Biofuse™ is underpinned by Croom Medical’s expertise in lattice design and material behaviour. OEMs can leverage this experience to replicate existing porous structures or explore new designs that improve fixation and manufacturability.

“With Biofuse™, customers can design lattices to their exact requirements,” said Dr. Bryan Naab, Additive Lead at Croom Medical. “That might mean replicating a porous structure previously produced through coating methods, or proposing lattice characteristics. The flexibility of the platform gives OEMs confidence that their design intent can be realised consistently and in line with regulatory expectations.”

Femoral Component with Biofuse™ 3D-Printed Lattice Structure manufactured using Laser-Powder-Bed-Fusion technology in CoCr.

Biofuse™ is now available through Croom Medical’s Additive Manufacturing offering, supporting projects from early design through to full-scale production. The launch highlights Croom Medical’s continued investment in additive manufacturing solutions for orthopedic applications.

For more information, visit www.croommedical.com/biofuse or contact [email protected]

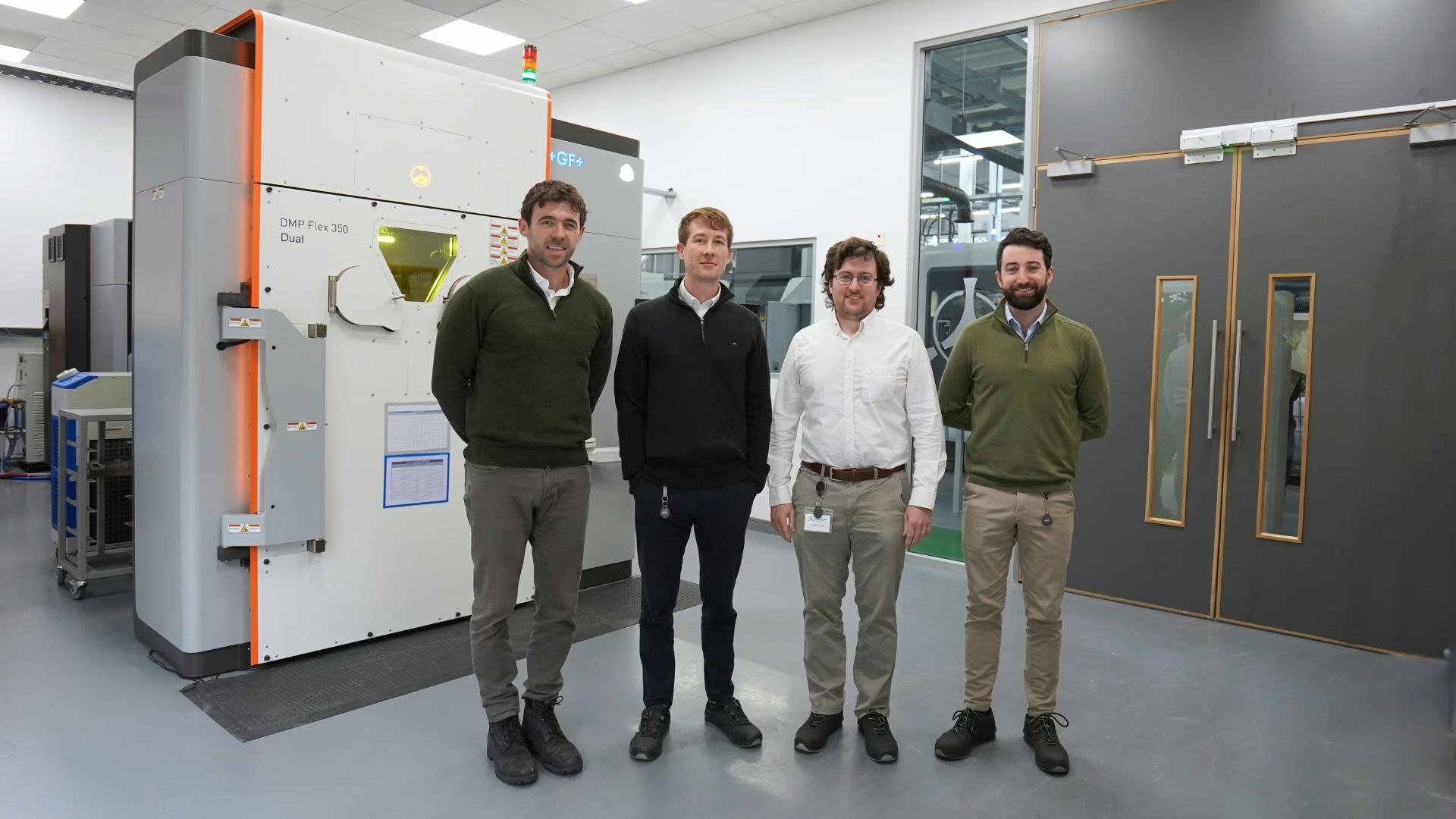

About Croom Medical

Croom Medical, based in Limerick, Ireland, is a contract manufacturer with 40 years of experience producing high-quality joint replacement implants for leading OEMs. Leveraging advanced manufacturing technologies and deep industry expertise, Croom Medical helps medical device OEMs accelerate time-to-market, boost production and secure their supply chain. Their FDA-registered and ISO 13485 certified-facility is supported by 150+ professionals, including an award-winning Research, Development & Innovation team.