Croom Medical, a leader in precision manufacturing for orthopedic implants, based in Ireland, is proud to announce the launch of TALOS™, an innovative technology platform developed in collaboration with Global Advanced Metals (GAM). TALOS™ is specifically designed for 3D-printing tantalum components across diverse industries, including medical applications , using advanced laser-powder-bed-fusion, setting a new standard in the industry.

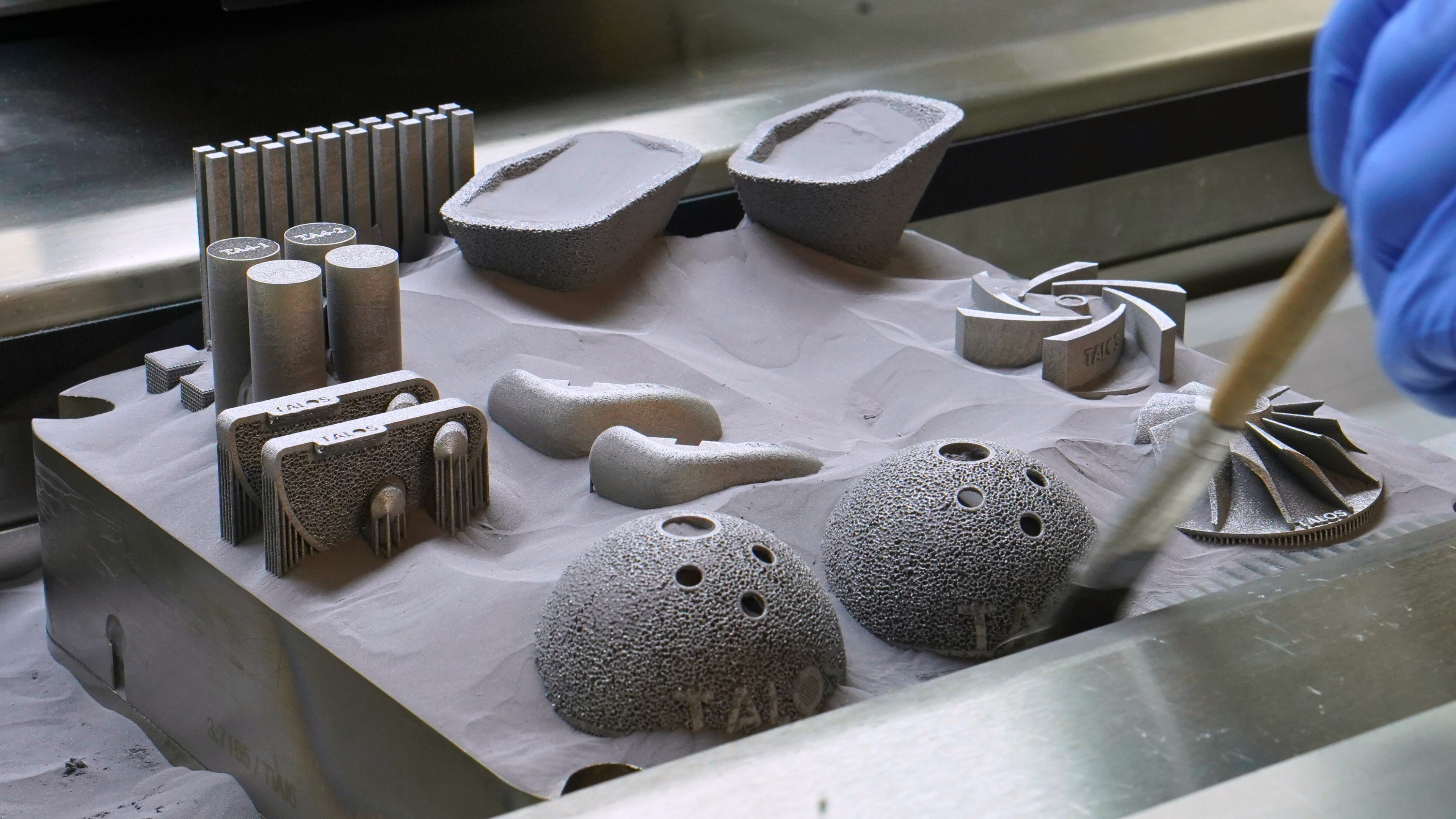

Tantalum is renowned for its exceptional biocompatibility, corrosion resistance, and mechanical strength , making it ideal for medical implants. However, its processing challenges have historically limited its widespread use. The TALOS™ platform overcomes these obstacles, enabling the production of complex, porous, strong and lightweight tantalum structures for medical device and industrial applications.

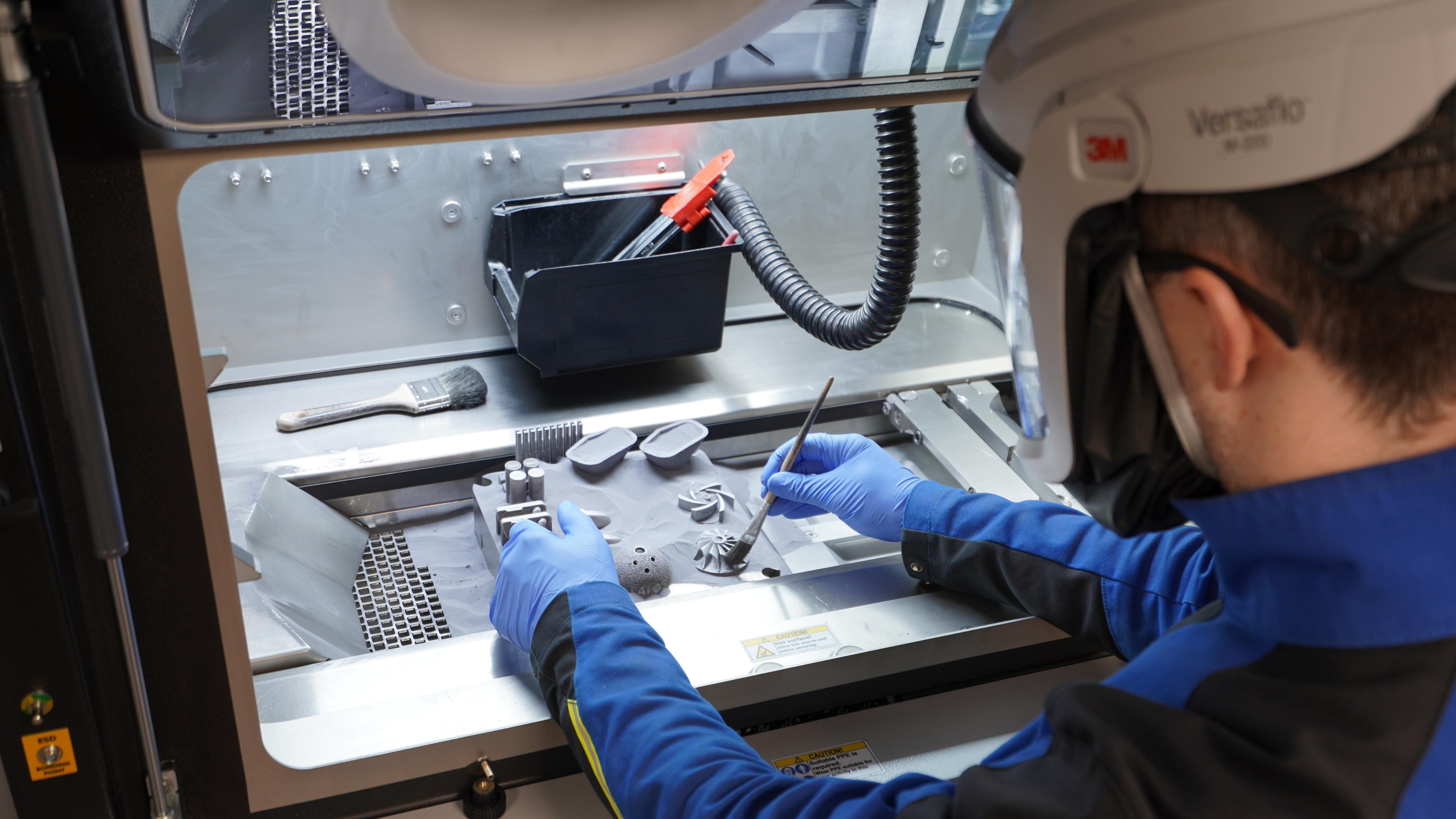

Tantalum components, manufactured using Croom Medical’s TALOS™ additive manufacturing platform, being carefully unloaded post-print.

Dr. Shane Keaveney, R&D Manager at Croom Medical, highlighted the significance of this advancement. “Tantalum has long been valued for its outstanding biointegration, corrosion resistance, and mechanical properties. With TALOS™, we unlock these intrinsic qualities, allowing precise control over implant ductility and strength to closely match native bone.”

TALOS™ is now commercially available through Croom Medical’s contract manufacturing services, supporting customer projects from prototype to volume manufacturing. Precise control over tantalum printing parameters and cellular lattice structure design enables engineers to tailor implant ductility and strength to match native bone. TALOS™ achieves densities up to 99.99% and delivers highly open porous structures ideal for medical device applications. Furthermore, AM-optimised tantalum is achieving over 40% elongation, reducing fracture risk and enabling complex, flexible designs.

Croom Medical’s additive manufacturing engineer operating the Colibrium Additive M2 Series 5 system, home to the TALOS™ platform.

A standout feature of TALOS™ is its ability to directly print tantalum onto titanium substrates, merging titanium’s lower density with tantalum’s osteoconductive prowess . This hybrid approach holds the potential for implants with enhanced bone fixation, representing a significant step forward in reducing the need for revision surgeries.

Sustainability is a core aspect of the TALOS™ platform. It uses ethically sourced, conflict-free tantalum powder supplied by GAM, supporting a closed-loop recycling process. “After 3D printing, leftover powder from Croom Medical is returned to GAM, where it undergoes rigorous refining and reprocessing before re-entering the manufacturing cycle. This approach maximises material efficiency and ensures a secure, consistent supply of tantalum”, explained Dr Gordon C. Smith , GAM’s CTO.

A selection of tantalum-based medical and industrial components, 3D-printed by Croom Medical using the TALOS™ platform.

Patrick Byrnes, CEO of Croom Medical, emphasised the company’s commitment to advancing manufacturing technologies. “TALOS™ aligns with our mission to advance manufacturing technologies, significantly improving patient outcomes by producing implants with superior biointegration, reduced stress shielding, and exceptional fatigue resistance. These benefits should lower the rate of surgery revisions, thus avoiding patient discomfort and unnecessary added surgery costs.”

Tantalum-based radial impeller produced using Croom Medical’s TALOS™ 3D-printing platform.

Beyond medical applications, TALOS™ offers significant advantages for the industrial and energy sectors. Its ability to craft complex near-net shape components incorporating advanced design features such as controlled porosity zones, cellular lattices, surface textures, and internal cooling or mixing channels, unlock efficiencies in demanding applications in power generation, chemical processing, and high-temperature operations.

Dr. Keaveney concluded, “The launch of TALOS™ positions us at the forefront of medical innovation, reinforcing our commitment to continuous innovation and advanced patient care.”

Croom Medical’s TALOS™ technology represents a significant advancement in additive manufacturing, offering flexible solutions that cater to both medical and industrial needs, and reaffirming the company’s dedication to innovation and excellence. For more information visit www.croommedical.com/TALOS or contact [email protected].