Few materials combine corrosion resistance, thermal stability, and biocompatibility as completely as tantalum. Once limited by its manufacturing difficulty, tantalum additive manufacturing is now redefining what can be achieved in medical, industrial, and energy applications. Through the TALOS™ platform, Croom Medical is pioneering new performance and design possibilities that extend far beyond traditional fabrication limits.

Why Tantalum Matters

Tantalum is one of the most capable refractory metals, with a melting point exceeding 3,000 °C and exceptional resistance to chemical attack. It retains mechanical strength under extreme heat, resists oxidation, and forms a stable oxide layer that protects it from corrosion, even in boiling acid. These characteristics have made it indispensable for demanding environments such as chemical processing, aerospace systems, and orthopaedic implants.

In the human body, tantalum’s biological inertness and ability to promote bone integration make it ideal for long-term implants. In industrial settings, its durability and stability outperform many high-value alloys. Yet, despite these advantages, conventional machining has limited its broader adoption due to cost, tool wear, and material waste.

Additive Manufacturing: A Turning Point

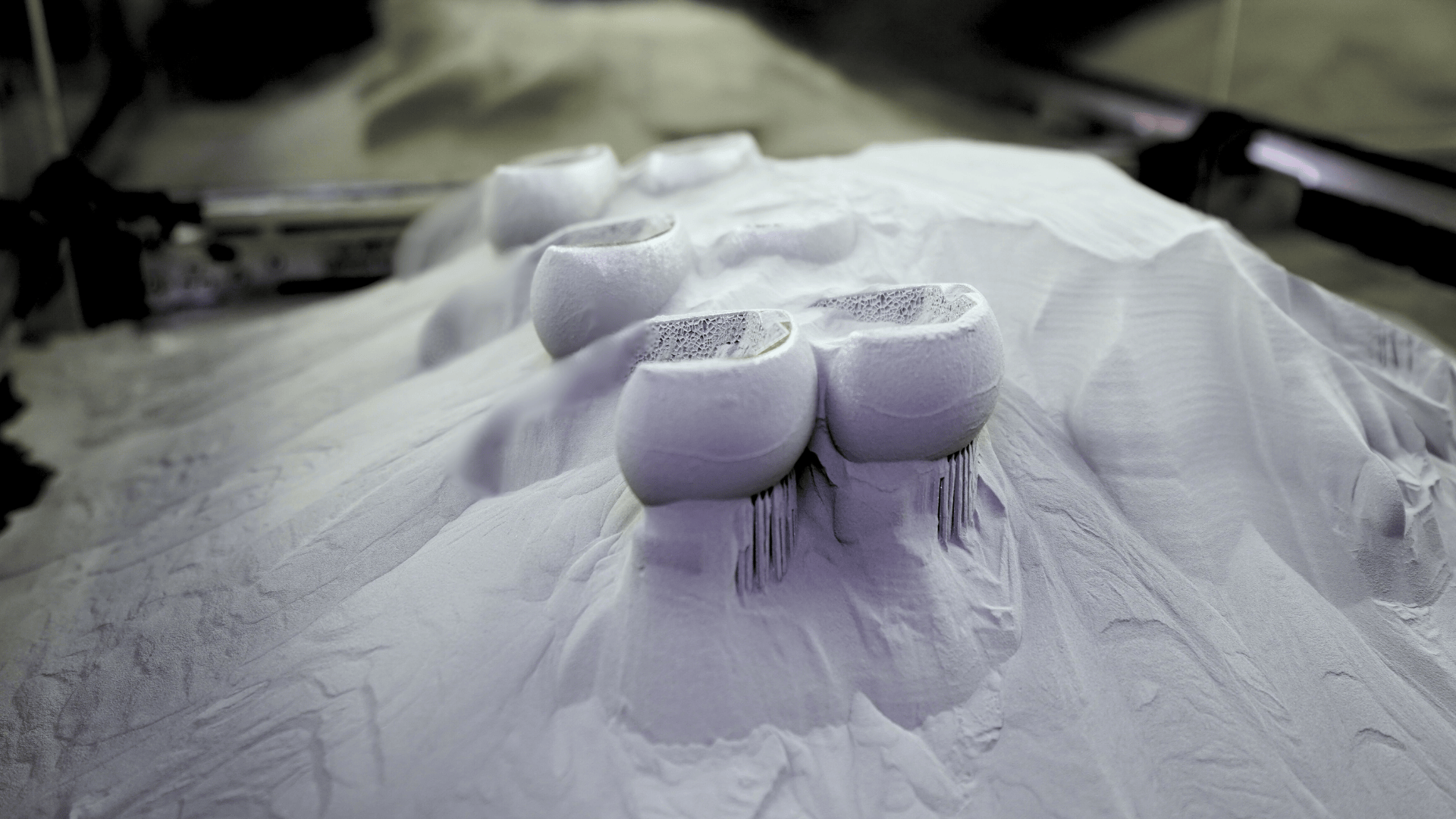

Laser Powder Bed Fusion (L-PBF) has changed what is possible with tantalum. By building components layer by layer from metal powder, 3D printing tantalum enables complex geometries, internal channels, and graded structures that could never be machined. It also reduces material waste, shortens lead times, and allows precise control over microstructure and density.

For Croom Medical, the introduction of the TALOS™ platform, developed with Global Advanced Metals (GAM), marks a technological milestone. It is the first industrial-scale AM process designed specifically for tantalum, achieving densities above 99.99 % of theoretical while maintaining elongation over 40%. These results demonstrate that AM tantalum can match or exceed wrought performance, even in extreme applications.

Key Insight: Additive manufacturing transforms tantalum from a niche material into a practical design tool for innovation across multiple industries.

Ethical and Sustainable Sourcing

Sustainability and traceability are critical for advanced material manufacturing. GAM provides a conflict-free tantalum supply chain certified under the Responsible Minerals Assurance Program since 2010. Most of its tantalum originates as a by-product of lithium mining in Western Australia, ensuring stable and transparent sourcing.

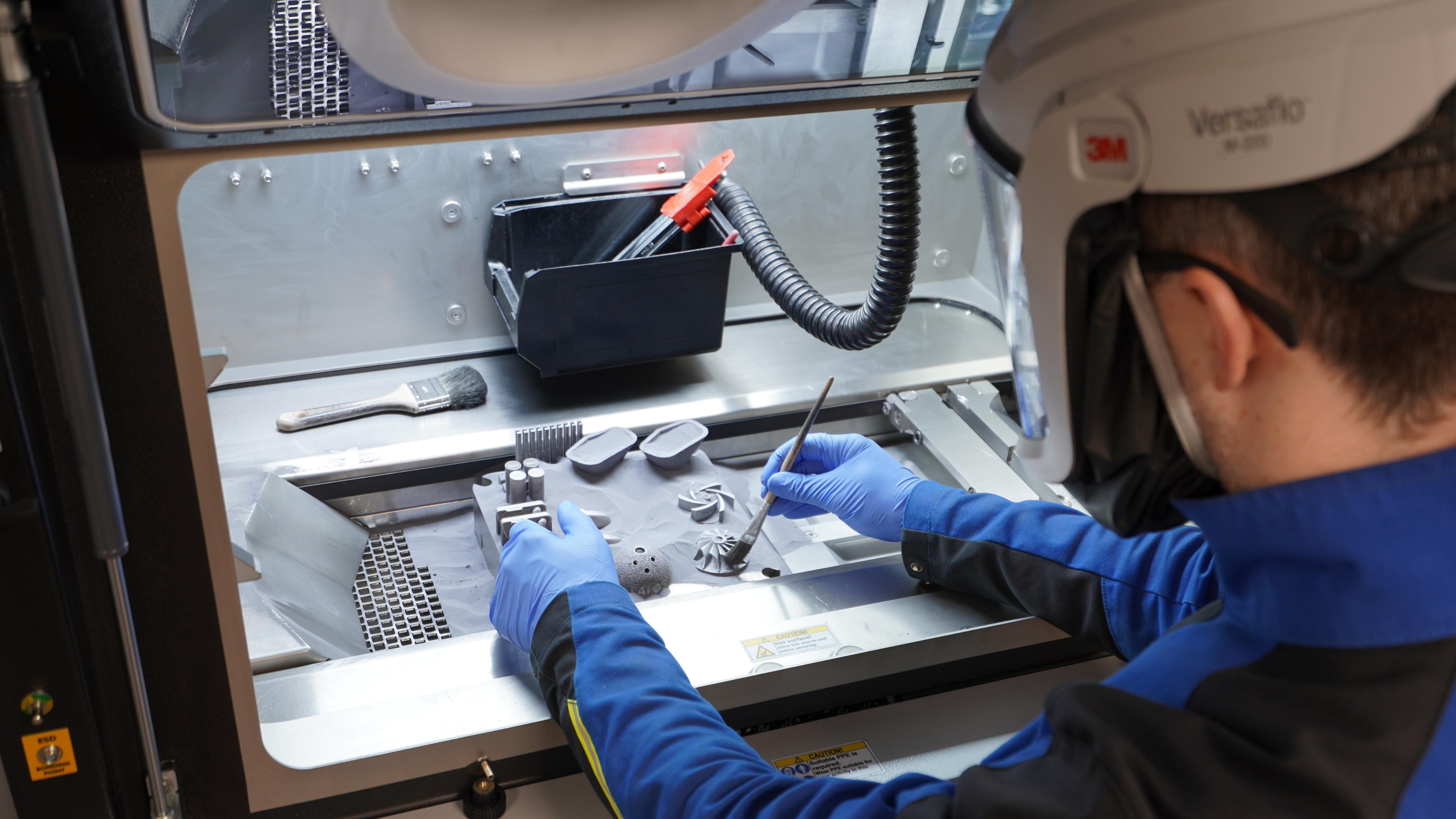

Within TALOS™, material stewardship extends to powder reuse. Over 95 % of unused powder is recovered and re-certified, establishing a near-zero-waste cycle. This approach aligns with Croom Medical’s commitment to responsible manufacturing while ensuring material purity for every build.

Expanding Beyond Medicine

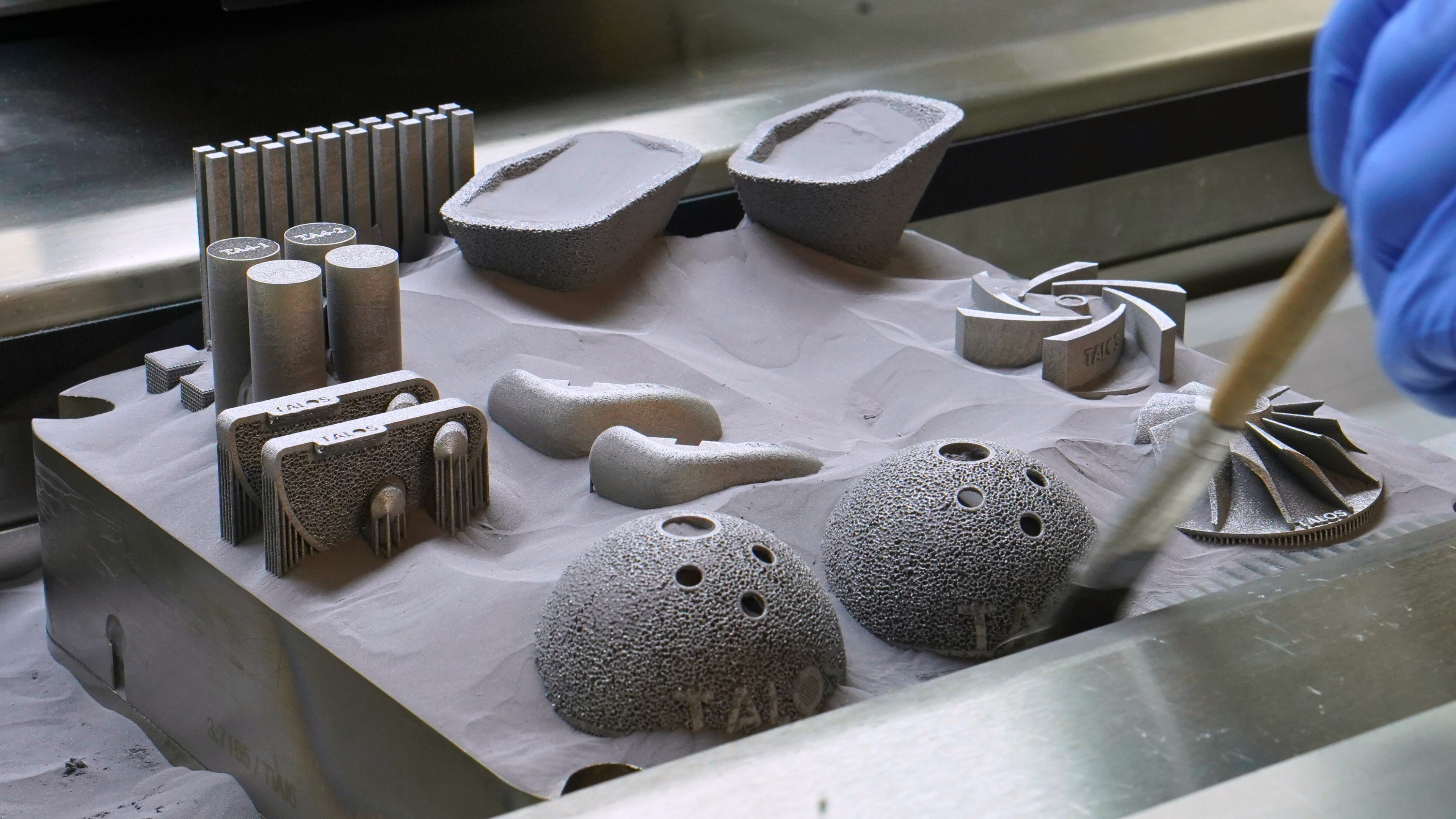

While tantalum’s medical role is well established, additive manufacturing opens new frontiers. Industries that demand corrosion resistance, high temperature performance, or mechanical strength now benefit from designs previously impossible to fabricate.

Electronics and Energy

Tantalum capacitors are vital for electronics due to their high charge density and reliability. In energy systems, AM tantalum is being tested in nuclear, turbine, and fusion applications where refractory stability is essential. For example, Croom Medical has produced TALOS™-manufactured components for UK-based First Light Fusion that endured shock compression exceeding 400 GPa, performing equivalently to wrought tantalum.

Aerospace and Defence

In aerospace propulsion, tantalum’s high melting point and resistance to erosion suit rocket nozzles and thermal barriers. Additive manufacturing enables lightweight lattice geometries that balance mass, heat transfer, and mechanical endurance, extending tantalum’s use in mission-critical systems.

Chemical Processing

In corrosive chemical environments, 3D-printed tantalum structures can be designed with internal mixing channels or enhanced surface area. This combination of corrosion resistance and design freedom improves reaction efficiency and component life in chemical reactors and heat exchangers.

Medical Innovation with 3D-Printed Tantalum

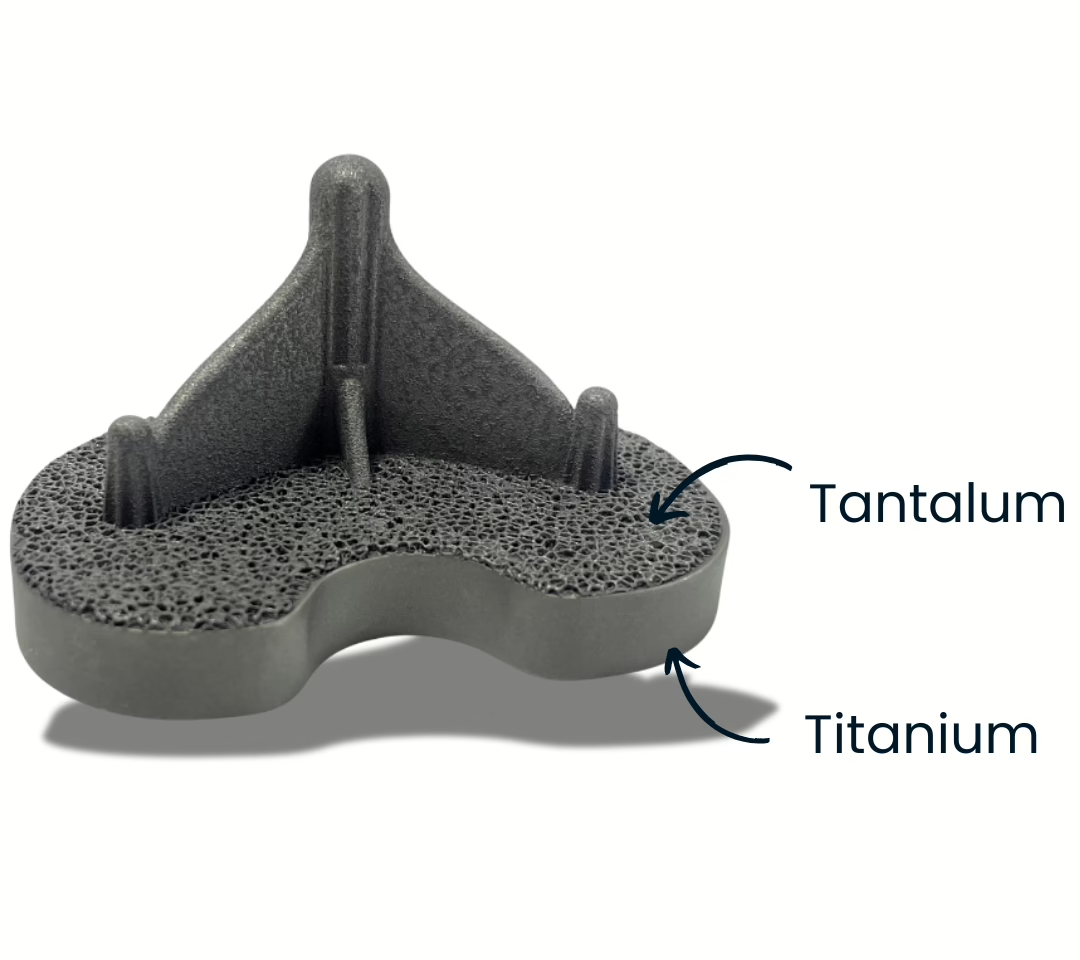

In orthopaedics, the synergy between tantalum additive manufacturing and advanced design delivers implants with tailored porosity and stiffness. These implants mimic natural bone, promoting faster osseointegration and reducing stress shielding. Unlike surface coatings that may degrade over time, a fully printed tantalum structure retains consistent mechanical and biological performance.

Croom Medical has also demonstrated hybrid builds, such as tibial tray prototypes where tantalum is directly printed onto titanium substrates. This combination leverages titanium’s strength and low density with tantalum’s bone-ingrowth potential. Early testing indicates a robust metallurgical interface, suggesting new opportunities for next-generation implants that combine mechanical and biological performance in a single build.

Radiopacity and Surgical Visibility

Tantalum’s radiopaque nature also supports its use as embedded markers in implants, assisting surgeons with precise positioning under X-ray or fluoroscopy. Such features add clinical value while maintaining the mechanical integrity of the device.

Performance Validation

Croom Medical’s in-house testing confirms that TALOS™-produced tantalum matches or surpasses wrought material in tensile strength and ductility. Porous structures show high bioactivity, while dense parts demonstrate mechanical resilience under extreme thermal and chemical conditions. These results validate AM tantalum’s potential for consistent, repeatable performance across sectors.

Insights from Croom’s ongoing research into additive titanium and lattice design are informing similar approaches with tantalum. Enhanced surface area, internal cooling networks, and graded mechanical properties are now within reach, pushing boundaries for future product development in both medical and industrial domains.

A Secure Path Forward for Refractory Metals

The market for refractory metals is small in volume but strategic in importance. Tantalum, with its unique combination of properties, is essential to high-value industries where reliability is non-negotiable. Additive manufacturing does not merely simplify its production, it expands the scope of what can be designed and achieved.

The TALOS™ platform illustrates how an integrated approach—from powder production to process validation—can remove barriers that once restricted tantalum’s adoption. Through close collaboration between Croom Medical and GAM, this technology demonstrates that complex refractory metals can be manufactured efficiently, sustainably, and at scale.

Outlook: Designing Without Limits

The convergence of material science, additive process control, and ethical sourcing is reshaping how engineers think about design. With TALOS™, we are unlocking a new level of performance for tantalum across medical, energy, and aerospace applications. The platform’s early success shows that 3D printing can deliver both design flexibility and industrial-grade reliability, transforming tantalum from a specialised material into a mainstream enabler of innovation.

Conclusion

Tantalum additive manufacturing is redefining performance and design boundaries in industries that demand the most from their materials. With its unique combination of strength, bioactivity, and corrosion resistance, tantalum is no longer constrained by conventional processes. Through the TALOS™ platform, Croom Medical demonstrates that advanced manufacturing can deliver both reliability and creativity, enabling a future of limitless engineering possibilities.

Connect with Croom Medical’s highly experienced manufacturing team for tailored solutions and industry-leading expertise. Contact us today.