Tantalum 3D-Printing

Tantalum 3D-Printing

with TALOS™

A next-gen technology platform harnessing Tantalum’s unique benefits with Laser-Powder-Bed-Fusion additive manufacturing.

Advanced Technology Platform

TALOS™ sets a new benchmark for tantalum-based 3D printing. Developed in collaboration with GAM Additive™, TALOS™ significantly reduces lead-times, costs, and waste while leveraging advanced additive manufacturing to achieve exceptional feature resolution.

Accelerated Production

Improved prototype-to-production timelines with rapid iteration using L-PBF technology. Available for customer designs from prototype to volume manufacturing.

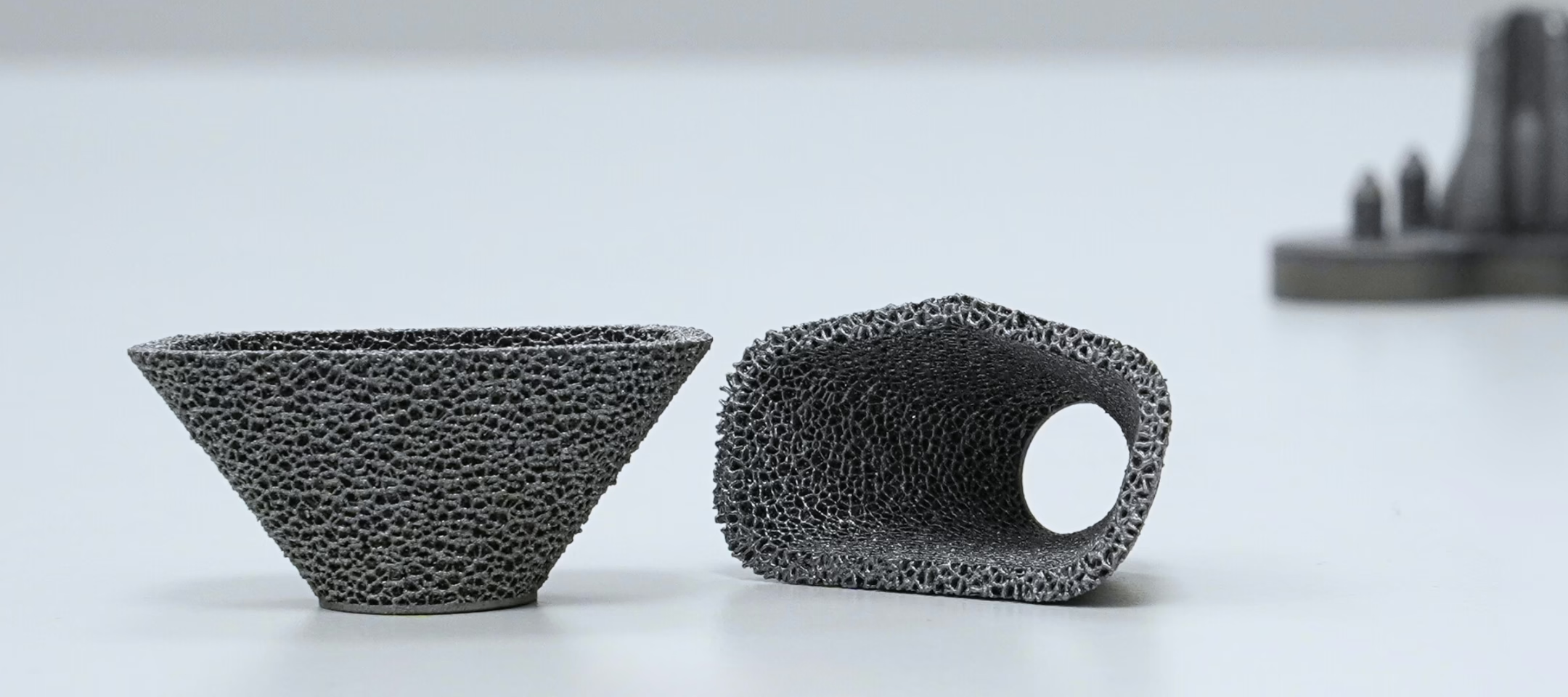

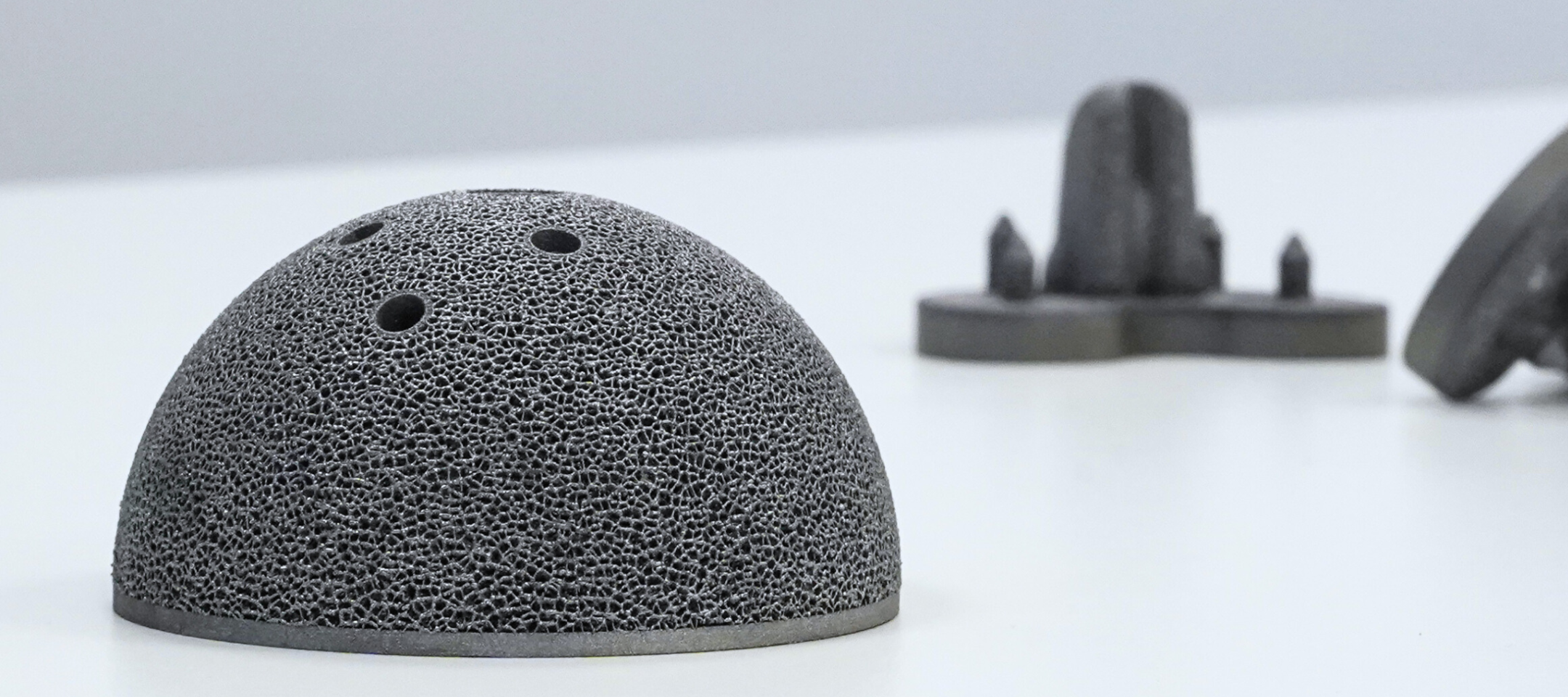

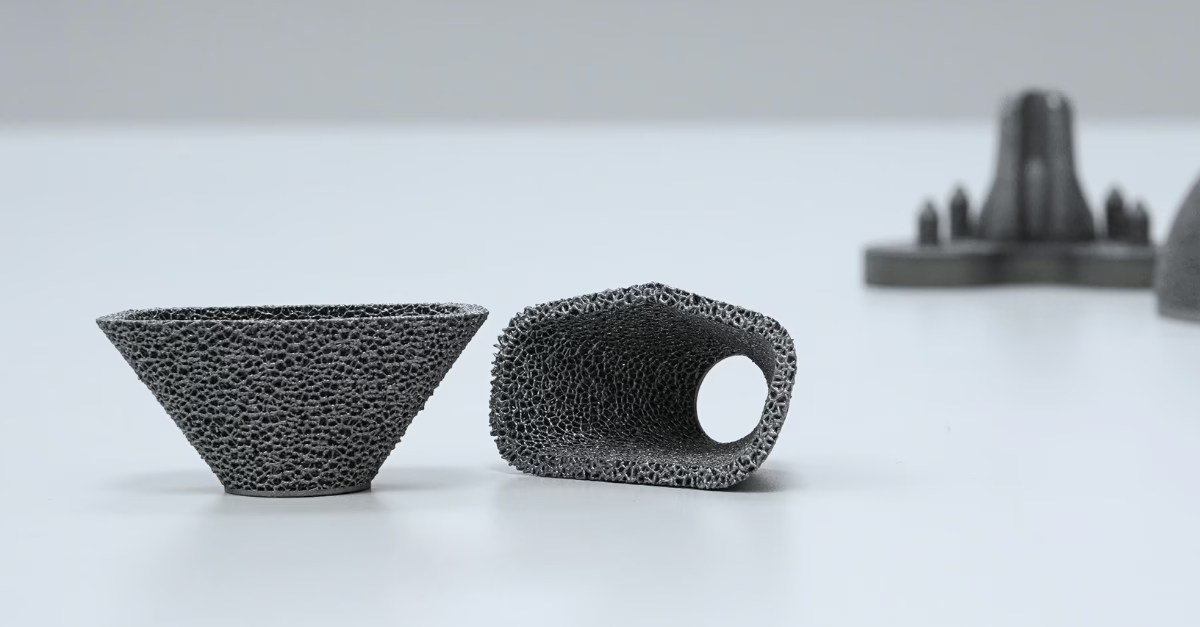

Porous Implant Printing

TALOS™ consistently produces fully porous tantalum implants that mimic natural bone architecture, enhancing bone in-growth and vascularization.

Customisable Properties

Precise control over printing parameters and cellular lattice structure design enables engineers to tailor implant ductility and strength to closely match native bone.

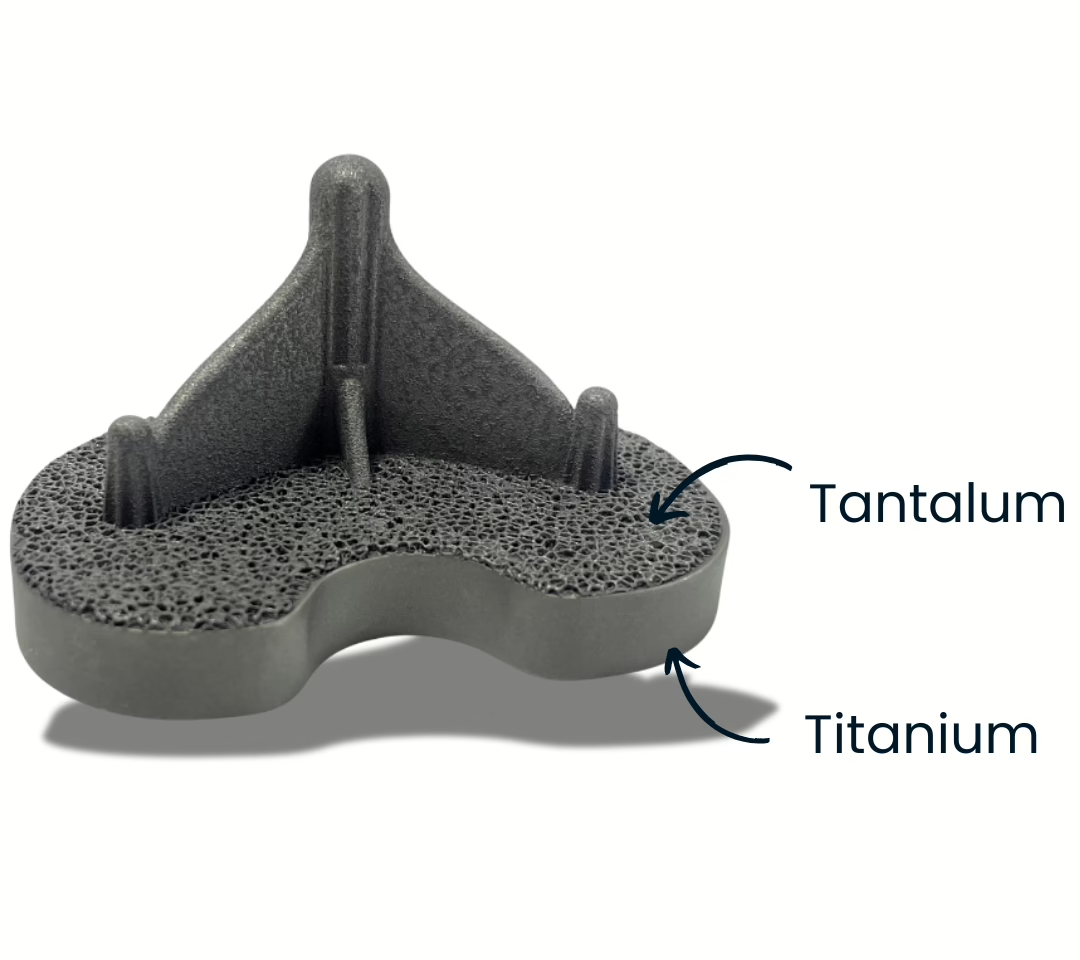

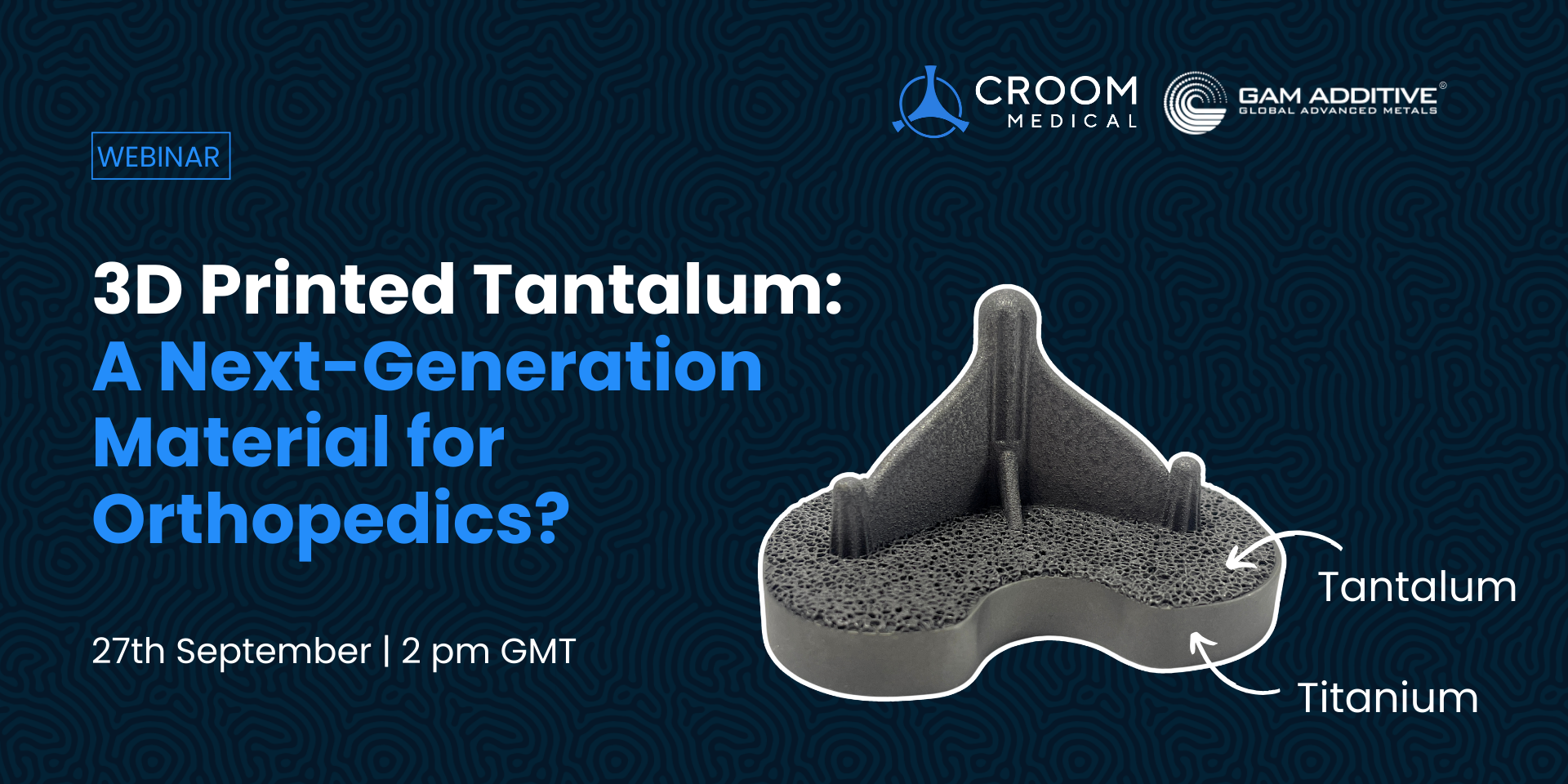

Direct Ti-Ta Printing

TALOS™ supports the direct 3D printing of tantalum onto titanium substrates, combining titanium’s lightweight strength with tantalum’s superior osteoconductive and corrosion-resistant qualities.

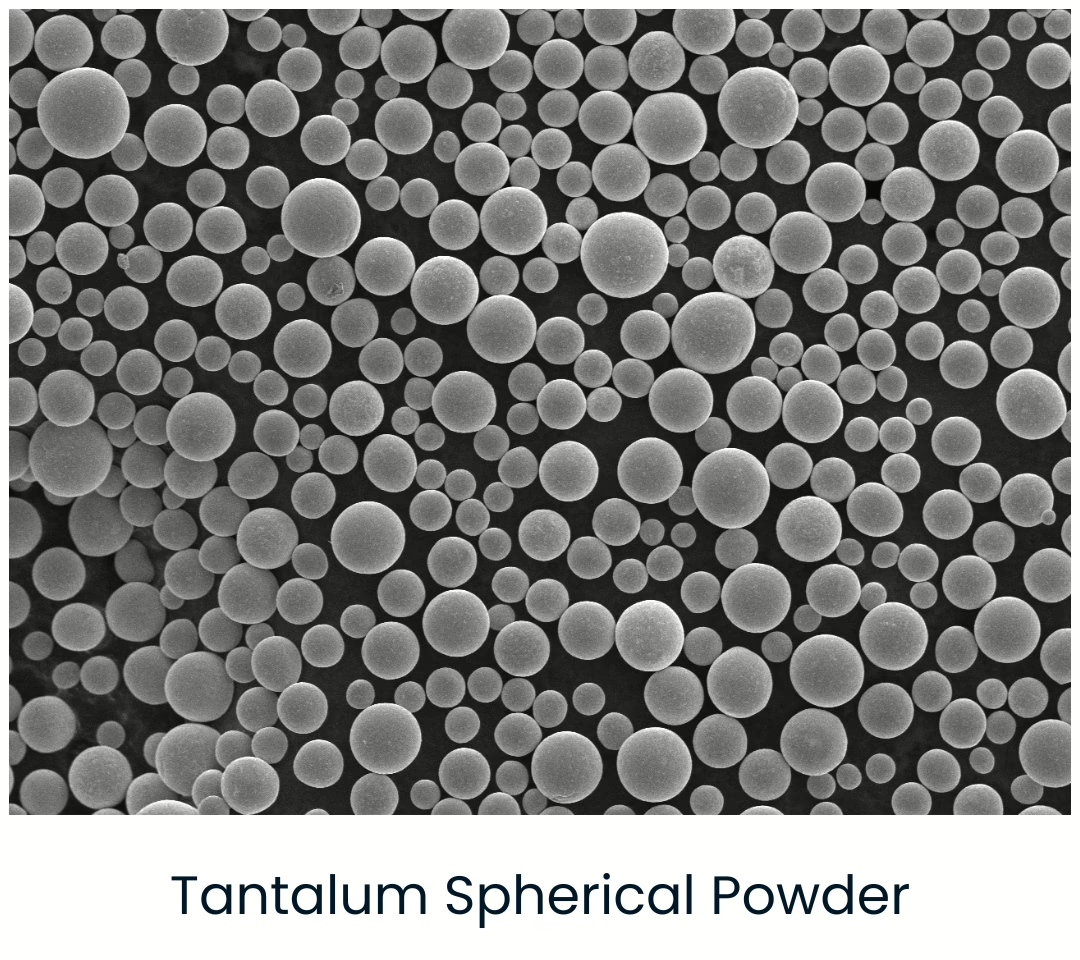

Secure Ta Powder Supply

TALOS™ utilizes ethically sourced, conflict-free tantalum powder from GAM Additive™ in a closed-loop recycling system. Securing our Ta powder supply, maximizing material efficiency and supporting sustainability.

Controllable Porosity & Density

TALOS™ achieves densities up to 99.99% and deliver highly open porous structures typical for medical device applications.

The purity and intrinsic properties of tantalum have a wonderful fit for next generation implants.

UNIQUE MATERIAL PROPERTIES

Distinct advantage for medical

Tantalum’s intrinsic characteristics make it an ideal material for orthopedic implants and devices. TALOS™ unlocks its full potential by offering:

- Superior Biointegration: Exceeds titanium and other metals in osteoconduction, osteogenesis, and osseointegration, accelerating bone growth and ensuring long-term fixation.

- High Radiopacity: Enhances imaging precision during surgery, simplifying real-time device positioning without costly alternatives.

- Ductility: AM-optimized tantalum achieves over 40% elongation, reducing fracture risk and enabling the fabrication of complex, flexible designs.

- Fatigue Resistance: Engineered to mimic natural bone mechanics, minimizing stress shielding and improving implant longevity.

biological benefits

Enhanced patient outcomes

Tantalum has been trusted in surgical applications since its discovery in 1802, valued for its biocompatibility, corrosion resistance, and mechanical strength. TALOS™ leverages these benefits to deliver:

- Biocompatibility & Clotting Resistance: Non-toxic, hypoallergenic, and proven safe in FDA-approved implants.

- Bone Ingrowth: Engineered porous structures enable cementless fixation, reducing revision surgeries and enhancing patient outcomes.

- Low Modulus Potential: Matches natural bone flexibility, reducing stress shielding and promoting seamless integration.

- High Surface Friction: Stabilizes implants during critical healing phases to mitigate post-surgical complications.

- High Normalised Fatigue Strength: Enables the implant to endure repetitive daily stresses, mimicking natural bone while reducing microfracture risk and enhancing durability.

TALOS™ supports our mission to advance manufacturing technologies to enable better patient outcomes.

CROOM MEDICAL x GAM ADDITIVE™

Collaboration Unlocks Ta Additive Capability

At the heart of TALOS™ is a strategic collaboration between Croom Medical and GAM Additive™.

By integrating Croom Medical’s advanced Laser-Powder-Bed-Fusion expertise with GAM’s ethically sourced, ultra-pure, sustainably produced tantalum powder, we deliver Ta-based structures and high-performance devices that meet and exceed industry standards. This collaboraation refines process parameters to achieve complex geometries and mechanical properties that match conventionally wrought tantalum.

TI-TA IMPLANTS

Delivering Hybrid Possibilities

TALOS™ goes beyond single-material printing with the ability to directly print tantalum onto titanium substrates.

This hybrid approach combines titanium’s strength and lightweight nature with tantalum’s superior osteoconductive and corrosion-resistant properties.

The result gives potential for a new generation of implants that are both mechanically robust and biologically active, setting a new benchmark in orthopedic innovation.

CLOSED LOOP SUPPLY CHAIN

With sustainability & efficiency at its core

Our closed-loop supply chain ensures every sphere of tantalum powder is optimized for performance and cost efficiency. Post-production, end of life Ta powder is collected and returned to GAM for recycling and reprocessing.

This innovative workflow minimizes waste while maintaining a consistent, high-quality supply of tantalum for future builds—delivering long-term value to our OEM partners.

INDUSTRIAL APPLICATIONS

Engineered to thrive in the industrial environments

TALOS™ extends its benefits beyond medical applications, delivering advantages for the industrial and energy sectors. Tantalum’s exceptional material properties, namely its extremely high melting point, very high density, outstanding corrosion resistance, and remarkable ductility, make it ideally suited for harsh applications such as power generation, chemical processing, and high-temperature industrial operations.

At the core of our TALOS™ offering is advanced Laser-Powder-Bed-Fusion technology, which provides precision control for fabricating complex geometries and tailoring porosity. This process can achieve complex near-net shapes with material density up to 99.99%. The inherent design freedom of additive manufacturing also allows for the incorporation of advanced design features that are almost impossible in traditional manufacturing. These include elements like controlled porosity zones, cellular lattice structures, surface textures, and internal conformal cooling or mixing channels.

Such precision capability and advanced design freedom enables the creation of advanced yet robust components that can greatly improve device performance and efficiency, whilst meeting rigorous performance standards and reducing tantalum material waste.

THE LATEST INSIGHTS

Observations on the Stability of Tantalum Powder during Laser-Powder-Bed-Fusion Additive Manufacturing

Authors: Dr. Matthew Osborne1, Dr. Gordon Smith1, Dr. Bryan Naab2 , Dr. Shane Keaveney2 Companies:1Global Advanced Metals (Boyertown, PA, USA) & 2Croom Medical (Limerick, Ireland) ...

3D Printed Tantalum: A next-generation material for orthopedics?

Watch the webinar on-demand here: https://youtu.be/-PIIkfxG5XU?si=uogjrdcvCMHATApy Stay Ahead of the Curve in Orthopedic Innovation with Croom Medical’s Upcoming Webinar in collaboration with Global...

Tantalum and the Evolution of Bone Interface Materials in Orthopedic Devices

The journey of material use in orthopedic implants has been a fascinating interplay of engineering, material science, and medical innovation. As the demands of patient ...

Ready to Innovate?

Join the growing number of industry leaders leveraging TALOS™ for next-generation orthopedic implants.

Contact Croom Medical today to explore how our AM capabilities, sustainable supply chain, and collaborative approach can accelerate your orthopedic device development and bring your innovative designs to life.