New research demonstrates how nitrogen-enhanced HIP cycles could unlock titanium’s potential in load-bearing applications

The orthopaedic industry is at a crossroads. For decades, cobalt chrome alloys have been the material of choice for wear-critical implant surfaces, particularly in knee and hip replacements. However, growing concerns around cobalt ion release, oncology risks, and sustainability are driving OEMs to seek viable alternatives.

Titanium has long been an attractive candidate due to its excellent biocompatibility, corrosion resistance, and compatibility with additive manufacturing. The challenge has always been its relatively poor wear resistance compared to cobalt chrome. New collaborative research between Croom Medical, Quintus Technologies, and Uppsala University may have found a solution.

The Challenge with Titanium in Wear Applications

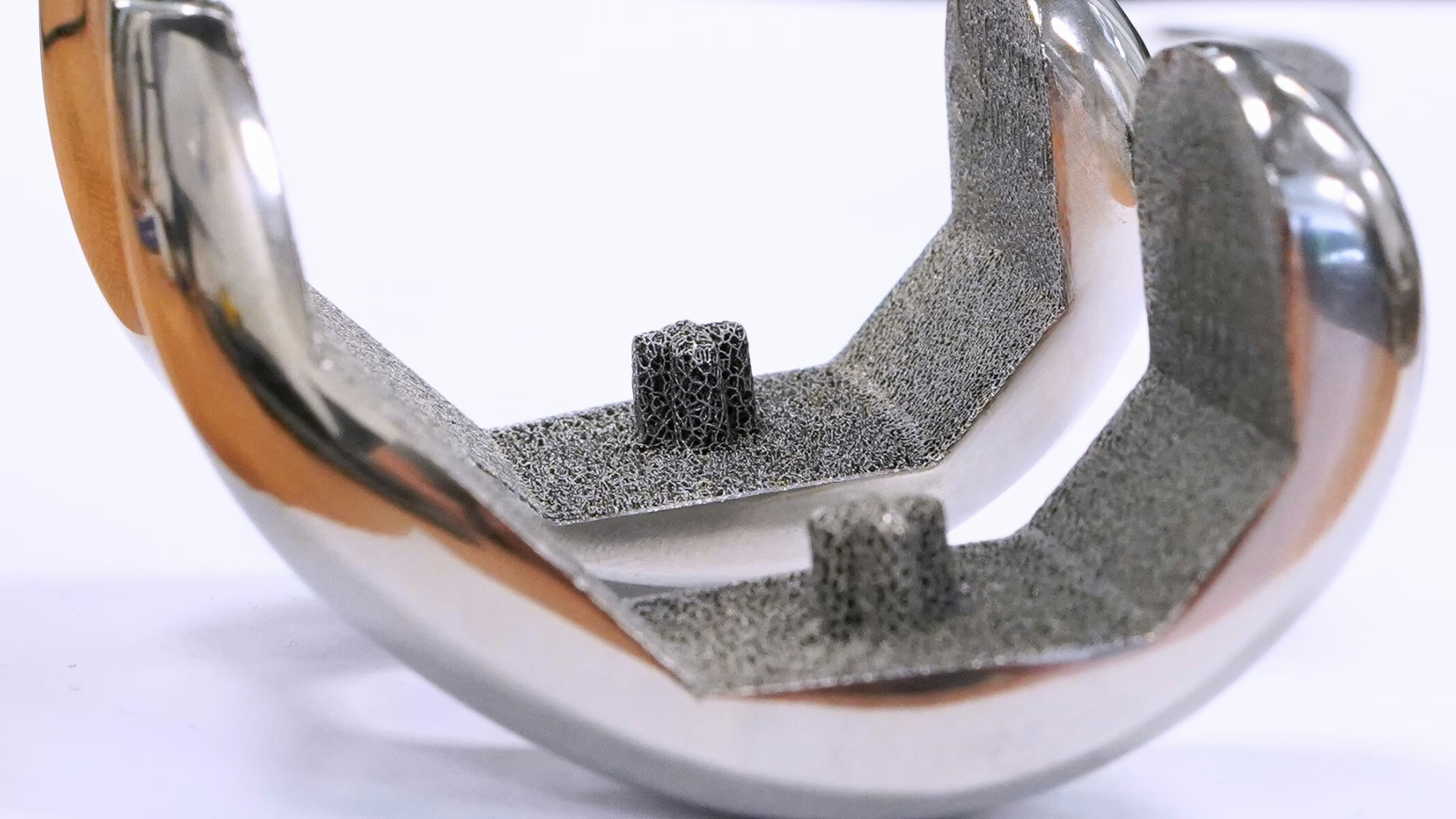

While titanium alloys such as Ti6Al4V (Grade 23) are widely used in orthopaedic implants for their biocompatibility and ability to support complex additive manufacturing geometries, they have traditionally been unsuitable for articulating surfaces. The material’s lower hardness compared to CoCrMo means higher wear rates, which can lead to debris generation and potential implant failure.

Current solutions involve applying wear-resistant coatings such as titanium nitride (TiN) through physical vapour deposition (PVD) or plasma nitriding. However, these processes add manufacturing steps, cost, and can suffer from delamination issues where the coating separates from the substrate.

A New Approach: Nitriding During HIP

The research, titled Adjusting the Wear Resistance of Ti6Al4V Using HIP, investigated whether protective TiN surface layers could be created during the Hot Isostatic Pressing (HIP) cycle itself, rather than as a separate post-processing step.

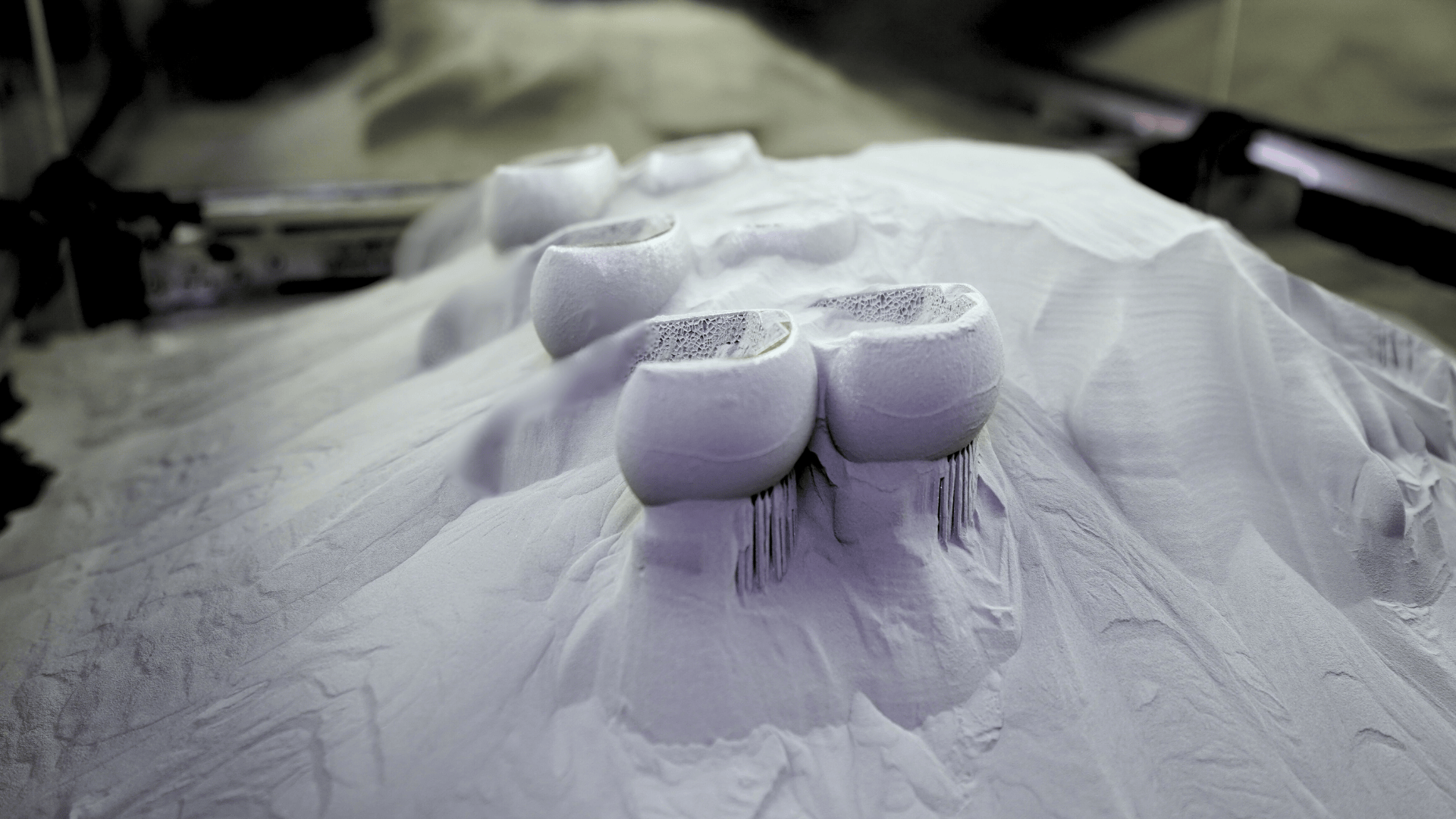

Samples were additively manufactured at Croom Medical using laser powder bed fusion (L-PBF) with Ti6Al4V Grade 23 powder. These samples were then processed at Quintus Technologies using HIP cycles with varying nitrogen concentrations mixed into the argon process gas. Uppsala University conducted the tribological testing and analysis.

Key Findings

The results were striking. Samples treated with nitrogen-enhanced HIP cycles showed:

Doubled hardness: Treated samples achieved approximately twice the hardness of as-printed titanium samples, with the TiN coating reaching around 600 HV.

Minimal measurable wear: Pin-on-disc testing revealed that wear marks were barely visible on nitrogen-treated samples, with wear tracks so minimal they could not be measured using vertical scanning interferometry.

No delamination: Critically, there were no signs of coating failure or delamination, a common challenge with traditional PVD and plasma nitriding approaches. The protective layer wore gradually without catastrophic failure.

TiN confirmed: EDS analysis confirmed the presence of titanium and nitrogen in the wear-flattened areas, indicating successful formation of TiN surface layers.

What This Means for Orthopaedic Manufacturing

The ability to create wear-resistant surfaces during the HIP densification cycle offers several potential advantages for implant manufacturers:

Process consolidation: Surface hardening can be integrated into an existing required step, potentially eliminating separate coating operations.

Material flexibility: Opens the possibility of using titanium in applications traditionally reserved for cobalt chrome, such as femoral knee components.

Additive manufacturing synergy: Titanium’s excellent printability combined with improved wear resistance could enable new implant designs that leverage both benefits.

Next Steps

While these findings are promising, further work is needed to optimise nitrogen concentrations and thermal profiles, understand long-term performance in simulated physiological conditions, develop qualification pathways for regulatory approval, and scale the process for production volumes.

Croom Medical will be presenting these findings at OMTEC 2026, where attendees can learn more about the practical considerations for implementing this technology.

Research Contributors

This research was made possible through the collaboration of:

Croom Medical (Limerick, Ireland) provided additive manufacturing capabilities and Ti6Al4V material. Dr. Shane Keaveney, R&D Manager, led Croom Medical’s involvement in the project.

Quintus Technologies AB (Västerås, Sweden) performed Hot Isostatic Pressing trials using their advanced HIP equipment with controlled nitrogen atmospheres. Mr. Jim Shipley authored the research.

Uppsala University (Uppsala, Sweden) conducted tribological testing and materials analysis through the Division of Biomedical Engineering. Contributors include Ms. Matilda Karlsson and Dr. Francesco D’Elia.

The work was financed by the AM4Life consortium project at Uppsala University. Material and printing were financed and provided by Croom Medical. Hot Isostatic Pressing was performed by Quintus Technologies.

Reference

Shipley, J., Karlsson, M., D’Elia, F., & Keaveney, S. (2025). Adjusting the Wear Resistance of Ti6Al4V Using HIP. Quintus Technologies AB, Uppsala University, and Croom Medical.

For more information about Croom Medical’s additive manufacturing capabilities for orthopaedic implants, contact us at [email protected].